Chanel’s Foray Into 3D Printing

Chanel, one of the most iconic haute couture houses, has been at the forefront of additive manufacturing compared to its peers. The brand recently debuted a 3D printed mascara that it had been perfecting for over a decade. While the jury is still out on if 3D printing will become an integral part of the luxury retail sector for the future, Chanel has taken a clear stance to invest in the technology for the long term.

Chanel, founded by Gabrielle “Coco” Chanel in 1913, has long been considered one of the most iconic haute couture houses. The brand came into prominence during the 1920s and embodies beautiful yet practical styles in its designs. Some of Chanel’s signature pieces include the classic cardigan and suit, the quilted handbag with a chain-link strap, and “the little black dress,” all of which continue to be highly relevant pieces in women’s wardrobes today1. Although Chanel passed away in 1971, the brand continues to innovate and create styles that embody Chanel’s legacy of elegant practicality. Chanel’s most recent innovation that has the beauty and fashion industry buzzing? A 3D printed mascara brush.

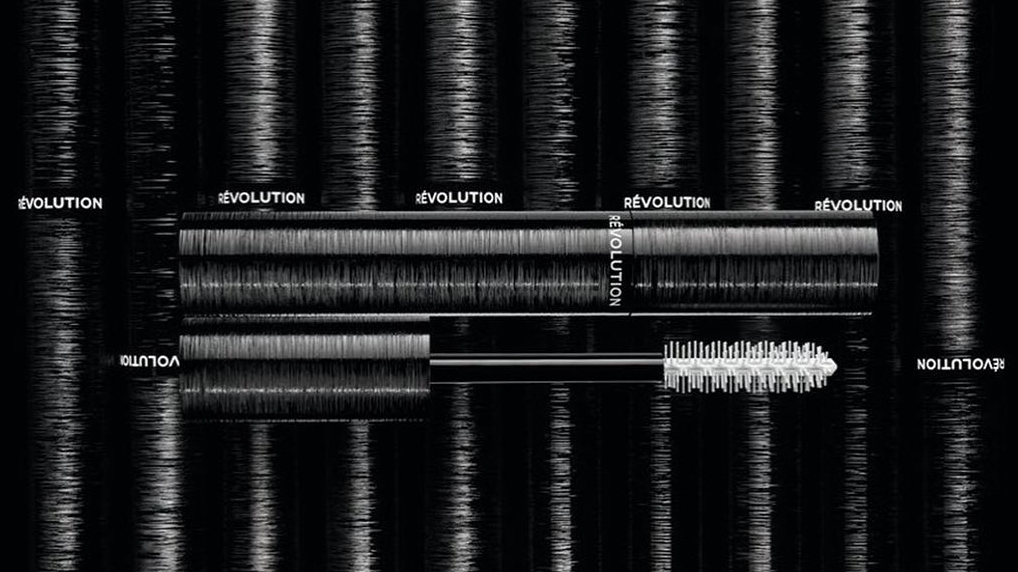

Since Iris van Herpen first debuted a 3D printed dress on the runway in 2011, the technology has been dubbed “the new disrupter” in the fashion industry2. The dress featured an “intricate white fabric scrunched-up into the shape of a Rorschach test,” and was considered one of the best inventions in 2011 by Time Magazine3. The fashion industry’s reaction to 3D printing has thus far been mixed, but Chanel has clearly taken a stance in favor of the technology. The brand announced its partnership with Epro 3D factory earlier this year to introduce the world’s first 3D printed mascara brush, Le Révolution Volume. The 3D printers at Epro are estimated to produce a total of 50,000 brushes per day, with a total of up to 1 million brushes each month5. Interestingly, this is not the first time Chanel has turned to additive manufacturing to drive innovation. In 2015, Karl Lagerfeld, the current head designer and creative director of Chanel, showcased a version of Chanel’s classic suit that embodied 3D printed technology. According to Lagerfield and his vision for Chanel, “what keeps couture alive, is to move with the times.4” Chanel’s foray into 3D printing has major implications for the brand, which has traditionally relied on its storied artisans for its innovation5. The use of additive manufacturing would not only propel the brand into the forefront of innovation among the old couture houses, but accelerate its initial prototyping and creation process at unprecedented speed. In addition, by utilizing 3D printing, the brand stands to save time and money by forgoing traditional injection-molding manufacturing processes, increasing the opportunity for flexibility and customization.

Chanel has clearly understood the potential 3D printing could have on the brand before other couture houses, and has invested resources into developing fluency with the technology since 2001 in the medium and short term. The brand filed to patent Le Révolution Volume back in 2007, with plans to roll out the mascara officially during Autumn of 20185. Chanel had gone through over 100 rounds of trials before the final shape for the mascara was created, but by utilizing 3D printing, the easily-customizable prototypes were created with low incremental cost6. In addition, Karl Lagerfeld’s experimentation with additive manufacturing on one of its most timeless pieces during the 2015 runway season attests to Chanel’s willingness to incorporate new technology and showcase them front and center. While Chanel’s investment in 3D printing have been dismissed as a short-term fad, the brand has always been comfortable playing the long game on bets in fashion, even if it stands alone.

While Chanel primarily focuses on medium-term investments, the brand should consider additional impactful actions in the short-term. Since 2015, Chanel has yet to debut 3D printing on its runways again after the initial buzz that was created. While uncommon among other couture houses, Chanel should take the risk and showcase additional couture and ready to wear Fall / Spring collections utilizing 3D printing with a focus on creating wearable, practical styles. The more Chanel develops its muscles on creating wearable pieces incorporating additive manufacturing, the more first-mover advantage it would enjoy, and realize a learning curve along with other additional efficiencies.

Looking forward, while the benefits of 3D printing are clear, Chanel also has reasons to remain wary. If Chanel makes the decision to incorporate 3D printed apparel regularly into its collections, can the brand sustain its exclusive image and timeless designs? While 3D technology has not advanced to the point of being able to produce high quality products on mixed textures for soft-lined goods, it likely is only a matter of time. In addition, there are concerns with intellectual property theft and counterfeit goods. Recently, MakerBot, a 3D printing firm, unveiled a digital desktop scanner that can scan an object and create a digital design file that can be replicated via 3D printing on the spot in record time. Would 3D printing contribute to the rise of counterfeit goods, already estimated at $500 billion a year globally7, that could be produced in the comfort of your own home? Chanel needs to be ready to address these challenges head on when the time comes. (Word Count: 798)

Sources

[1] Mukti Khaire and Kerry Herman. “Coco Chanel: Creating Fashion for the Modern Woman” HBS No. 9-812-001. Boston: Harvard Business School Publishing, 2016.

[2] Butler O’Neal, B. (2015, December 21). 3D Printing Will Disrupt Fast Fashion, Help Eliminate Sweatshops, Empower Consumers, 3D Printing.com. https://3dprint.com/111778/3d-printing-fast-fashion, accessed November 12, 2018.

[3] Logan, L. (2016, November 6). The Dutch Designer Who Is Pioneering the Use of 3D Printing in Fashion. Smithsonianmag.com. https://www.smithsonianmag.com/innovation/dutch-designer-who-pioneering-use-3d-printing-fashion-180957184, accessed November 12, 2018.

[4] Hipolite, W. (2015, July 15). Chanel’s Karl Lagerfeld Stuns the Celebrities With 3D Printed Fashion Design. 3Dprint.com. https://3dprint.com/79654/chanel-lagerfeld-3d-printed, accessed November 12, 2018.

[5] Saunders, S. (2018, March 20). Chanel Turns to Industrial 3D Printing to Develop the First 3D Printed Mascara Brush. 3Dprint.com. https://3dprint.com/207267/chanel-3d-printed-mascara-brush, accessed November 12, 2018.

[6] Gallon, V. (2018, March 19). Chanel takes a major step with a 3D-printed mascara brush. Premium Beauty News. http://www.premiumbeautynews.com/en/chanel-takes-a-major-step-with-a,13110#, accessed November 12, 2018.

[7] Gallon, V. (2018, March 19). 3D Printing In Luxury Fashion: Revolution Or Evolution? Forbes. https://www.forbes.com/sites/herbertrsim/2017/12/03/3d-printing-in-luxury-fashion-revolution-or-evolution/#b7fdac53f205, accessed November 12, 2018

I think the questions you pose are very interesting. In my mind, the counterfeit risk is definitely of concern. If these machines are able to exactly replicate these products so consumers are not able to differentiate the difference between “real” and “fake,” then there are no incentives for them to spend more for a “real” product. I think the question here is what are the additional investments needed / how feasible is it to create new products with the current printer Chanel has today as it looks to expand both within and outside the beauty industry – a breakeven analysis could be helpful here.

It is interesting to think about 3D printing as cutting down R&D costs for a company like Chanel by reducing incremental dollars spent on prototyping mascara, since I suspected their runway collection 3D printed garments were more for show than for cost efficiencies. Along those lines, I wonder if they are looking into whether 3D printed components could be used for any of their garment production. That being said, they are likely to get more press for customer-facing 3D printed products than they would for back end improvements, so it all depends on whether their motivations are more focused on cost reduction vs. upside

In addition to the concern of counterfeits, I wonder if additive manufacturing could also harm the perceived quality of Chanel’s products. Like many couture brands, part of Chanel’s appeal is the high quality of its products and the craftsmanship that goes into each. While quality and craftsmanship are less relevant concerns for mascara and other makeup, Chanel could nonetheless experience a degree of perceived quality erosion by turning to 3D printing in its production process. If such a practice were to extend beyond makeup and into clothes, handbags, and shoes, Chanel would run a significant risk of losing much of the prestige that allows it to innovate in the first place.

Arting – Thanks for the interesting read. While I was reading the essay (and before I got to the last paragraph), I had exactly the same question as your question #1. With 3D printing, can Chanel keep its luxury brand image and cachet? For example, people love buying handbags that are “made in Italy / France,” which is why ultra-luxury brands insist on manufacturing their handbags in Europe vs. outsourcing to Asia, where they can manufacture at a fraction of the cost in Europe. In the case where Chanel expands 3D printing to its apparel and handbags, I do wonder how consumers would react to “made by 3D printing” tag on their products.

On the counterfeit point, I think it concerns all industries where 3D printing can be used. 3D printing will lower the bar for people to create counterfeit products, which will become a problem especially for branded consumer goods companies. I agree with you that companies who are venturing out into 3D printing should consider any potential consequences of having their products being copied easily by 3D printing.

Thank you for writing such an enjoyable piece! I’m curious as to what you think will be additive manufacturing’s biggest value proposition for Chanel — cost savings or brand growth, or perhaps Chanel is planning to explore first and answer the question along the process of discovery. There is generally a benefit to having the first-mover advantage, but in the case of 3D printing, if each haute couture house were creating their own pieces through additive manufacturing, what is the advantage you see Chanel having and maintaining by being first? To Justin’s point, are they at risk of being in a rush without considering the brand damage they may incur?

Thank you for the read, Arting. I have a few reactions:

(1) Isn’t 3-D printing essentially table stakes for Chanel now? Other competitors will have surely caught on by this point, which compels Chanel to maintain its competitive cost position through 3-D printing. I’m not persuaded by the idea that the products will lose cache/brand, since most customers will not be exposed to those more internal operational matters, unless this somehow gets outed as a PR nightmare.

(2) Does the counterfeit question, which poses a seemingly inevitable reality that price pressures downward will depress margins, imply that Chanel should abandon its position in this medium-term? Until 3-D printing reaches critical mass among competitors, Chanel can capitalize on its healthy margins and pricing power through its cache. But would it actually be more appropriate to sell of those businesses to lower-cost competitors, so that capital can be deployed elsewhere? I personally am with you that this side of Chanel’s business seems like a short sell.

What a great, haute article. I agree that if Chanel is not methodical in their incorporation of additive manufacturing into the production of their line that their timeless brand could be at risk. One way they could address this concern is by creating brand policies. For example, they should never create or reproduce any of their iconic pieces via additive manufacturing. That way, they can evolve to have a separate, futuristic line while maintaining their timeless allure.

I love this idea. Thanks Arting for such a great inside look into how one of the most iconic fashion houses is incorporating additive manufacturing into its new product development. I think introducing the technology in their cosmetics line, which has fewer connotations of manual artistry, was a smart move. But as you rightly point out, this technology has implications for its apparel business as well. Given that most of the major fashion houses have already separated haute couture from pret a porter, I don’t see too much risk to the brand if additive manufacturing is introduced in the more mainstream lines but kept out of made to measure couture. The fact that Chanel is among the first of the luxury houses to use this technology to me is in keeping with their pioneering spirit, which started with Coco wearing trousers when other women would never dream of doing so.

Great post Arting. As you’ve called out, by utilizing 3D printing, Chanel stands to save time and money by forgoing traditional injection-molding manufacturing processes, increasing the opportunity for flexibility and customization. If we imagine a world in which Chanel is able to go to market very quickly, do they risk losing their luxury perception as they start to look more like a fast-fashion brand?

Arting, I think you had a very valid point that 3D printing for Channel will raise the issue of counterfeit goods. I think that will definitely worsen the situation in the counterfeit goods market.

On another note, I also agree with SkyDecktecitive. Another issue I can foresee from this technology advancement is that having 3D printing might devalue Chanel’s luxury brand value. While 3D printing lowers the cost of production, it might eliminate the careful hand-made process, which is the signature of the luxury brand and eventually reduce the brand value. To avoid this risk, I think Channel should strategically select when to use 3D printer on the production. At the same time, the need to balance how they would communicate the use of 3D printing technology or marketing the products without devaluing its luxury brand.

I enjoyed reading this so much Arting! I didn’t know Chanel used 3D printing since 2011. It seems like Balenciaga also started using 3D printing to make seamless jackets for their collection this year : https://3dprintingindustry.com/news/balenciaga-3d-printing-fashion-130162/

It sounds quite innovative but I agree with the comments above. Will Chanel’s brand value be negatively impacted by using 3D printing? It’s benefit – quick, accessible – does not go well with “luxury”.

Or is there any benefits of using 3D printing other than cost/time savings? For example.. Can 3D printing make a new type of fabrics, or complex / innovative apparels that handcraftmen cannot do? If so, will Chanel’s customers value such innovation? I think such questions should be delicately adressed before adapting the 3D printings more into their manufacturing process.

Interesting article on an unexpected use of 3D printing! Aside from the concern about counterfeit goods, I think there is a danger in diluting the “luxury’ brand of Chanel with preconceptions about lesser quality of 3D printed goods (whether this is true or not). I think luxury is associated with high labor, hand-crafted goods, and while forward thinking design and innovation are important for the company, customers may begin to question the high markup on a good that can be so easily reproduced. To combat this and strike a balance, I wonder if they can use 3D printing for fast prototyping, but then more traditional processes for the full manufacturing process.

Thank you for this thought-provoking piece, Arting. Your question about whether incorporating more 3D printing into Chanel’s body of work would detract from its embodiment of timeless design made me think of further implications of this technology on Chanel’s design process. Your question addresses the quality and style of the designs and made me think additionally of the breadth of creativity within the designs. Instead of broadening the fashion house’s design portfolio, do you think the goal of incorporating more 3D printing could have the opposite effect and instead limit what kinds of ideas are brought to fruition? Would designers start having tunnel vision towards designs that would be a good match for 3D printing? I think @jlaydon’s suggestion of maintaining a balance between traditional manufacturing for Chanel’s age-old pieces and 3D printing for innovative designs could mitigate this concern in addition to hedging the risks of counterfeit production.

Great article, Arting! It will be very interesting to see the evolution of 3D printing in the fashion world. I think it’s remarkable that Chanel is venturing into the 3D printing world since, as a few people have pointed out above, it makes them highly susceptible to counterfeit which is already one of the biggest concerns facing haute couture fashion. Chanel and the world of haute couture differentiate themselves by their design and their craftsmanship, and bringing 3D printing into the process commoditizes the value of their craftsmanship. However, I do understand their use of 3D printing in makeup, which is mostly based on colour and formulation and not the craftsmanship of the product. I foresee a further gap between high fashion and high street brands as high street brands move to 3D printing (and hopefully away from exploitative labour practices in developing nations) and high fashion brands leverage an artisanal positioning but it would be curious to see how high fashion would distinguish themselves and prevent brand erosion if they continue to embrace 3D printing.

Arting, this is really interesting, thank you for sharing! To answer your questions, I think that Channel is a trend setter and that they can totally use 3D printing while sustaining their exclusive image in the short and potentially medium term, while 3D printing is still a novelty. Overtime, as the cost of 3D printing decreases and becomes more widely used in the apparel industry, I think that Channel will face some challenges with brand image. To address your other question, while counterfeit is a threat right now I have to assume that the regulatory will adapt and present new ways for companies to mitigate this risk through various technological solutions. Seeing as it will be recorded digitally somewhere instead of being handmade it may actually be easier to identify and shut down counterfeit operations.

I love this post! I think Chanel is definitely on the right track by incorporating 3D printing into its brand. I agree with the Lagerfield quotation that high fashion needs to evolve with time. I think Chanel can stay exclusive if they use 3D printing as a way to supplement their designs to make them more personalized rather than use 3D printing to mass produce. Personalizing pieces further will only add to the add to the brands luxury image and consumer loyalty. In terms of counterfeit goods, I am not that worried about counterfeit goods. There are already lots of copy cat versions of Chanel bags and products. People still always value the real version more. Perhaps there can be some non-3D printed label that is placed on all “real” items.

Great Article! I believe 3D printing has a huge potential for luxury products in terms of operational efficiency, however I believe that we are still far from unlocking its true potential. In my opinion there is still a great barrier in term of quality to be overcome, specially if we are dealing with an industry that relies on the materials property to create value (e.g. how a fabric adapts to a body) and plays in a industry that innovation is necessary to maintain competitive advantage (e.e. sustainable fashion, etc). I believe that 3D will bring a new challenge for Channel: the tradeoff between innovation in production and innovation in design. In a industry where innovation in design plays a big role, 3D printing impact will be limited in the near term.

Thank you for the interesting read, Arting. An interesting question/ concern with additive manufacturing in the fashion industry is the vast amount of energy it takes to keep plastic heated and malleable at high temperatures. I guess there must be certain types of materials that if used, power usage can be drastically decreased potentially making this type of printing greener than any other type of manufacturing. Regarding your point on counterfeits, one of the most promising design houses, XYZ Workshop, was able to make a 100% desktop printed dress using flexible PLA for around $100 in materials. That’s a price tag most people can handle and the dress looks totally wearable. What’s more striking, though, is the fact that they also released detailed step by step instructions so people can make their own.

Arting, thank you for your post! I am a bit surprised that of all clothing/beauty brands to venture into 3D printing, Chanel is at the forefront. Given the ‘timeless’ appeal of the brand, I am not surprised that they came to market with a 3D mascara, instead of with one of their higher grossing products, such as a handbag.

As a consumer, if I’m spending thousands of dollars on a handbag or piece of clothing item, I’d much rather it be handmade than made by a 3D printer. One reason is that the item seems more authentic if it is handmade. The second, is I’m not sure if 3D printing is currently advanced enough to ensure the clothing or handbag is pliable/durable enough. [1]

I’m interested if in the medium-term consumer perceptions about how authenticity and value as it relates to production will change, as well as if 3D printing can become advanced enough to actually produce similar quality products to the quality of Chanel’s products today.

[1] D. Spaeth. 3D printing is changing the face of multiple industries. ECN: Electronic Component News 61, no. 9 (October 2017): 21–23.

Thanks for the great post. I share your concern about Chanel risking harm to its brand by leaning into 3D printing across its lines too aggressively. However I think the first mover advantages and manufacturing learning efficiencies that come from upfront investment in 3D printing far outweigh the potential brand risks. Is there a way they can develop the technology in a more private way in house in order to slowly gauge what public perception will be over time?

Fascinating piece on additive manufacturing in an industry typically not associated with 3D printing, Arting! I definitely recall the splash of news following the 2015 Chanel show regarding the 3D printed pieces. And I certainly agree that a risk of using more 3D printing technologies in fashion risks counterfeits and mimicry from others. I echo Irene’s points around how Chanel can take advantage of this “first-mover” position in 3D printing — are there trends and accessories that they can drive with 3D printing? Perhaps even an extension of that — do you think that fashion should move further into technology? Should Chanel invest in selling a home 3D printer that can make custom mascara or lipstick colors? Or Chanel-branded fashion accessories? Or would these technologies further risk cannibalization of the luxury status brand if there are counterfeits?

This is great Arting! I think the combination of fashion houses and 3D printing will actually be a very powerful one. Fashion houses are known as bastions of creativity where creativity largely flows down from a single visionary. 3D printing can open up so many possibilities (especially in fashion, where aesthetic designs, once three-dimensional, can be endless), but the number of options can actually be paralyzing. Constraints are a phenomenal catalyst of innovation. When an iron-fisted design vision takes advantage of this technology, however, I can only imagine what might be thought up.

The impact of technology on creative industries, such as Chanel, is something that always grabs my attention. In high fashion, the heritage and craftsmanship of the artisans has traditionally been the driving force behind a brand’s reputation and the high price tag. This is something you mentioned as you said, “[Chanel]…traditionally relied on its storied artisans for its innovation.” But for Chanel, can 3D printing augment their current creative process, bringing productivity gains and cost efficiencies, without completely replacing the role of the artisan? I feel as though for this to happen, 3D printing should not be front and center for Chanel when talking about a specific collection or item, but rather it should be considered another tool in the toolbox for the artisans to create one of their pieces. With this, I do think Chanel can incorporate 3D printed apparel into its collections while sustaining its exclusive image and timeless designs. I am sure Chanel, over the years, has utilized other innovations in their manufacturing, prototyping, and production processes to-date but those innovations are not top of mind when we visit a Chanel store.