Sustainability in the apparel industry: Just do it.

The apparel industry is a significant carbon polluter and water waster, and Nike has led the industry with its sustainability practices.

Sustainability in the apparel industry: Just do it.

A Case Study on Nike

The apparel industry accounts for 10% of global carbon emissions and is the second largest industrial polluter. [1] This can be partially explained by the size of the apparel industry, with estimates as high as $3 trillion, given that 150 billion garments, or 20 per person, are produced annually.[2]

Context: Apparel Industry and Climate Change

Carbon Emissions

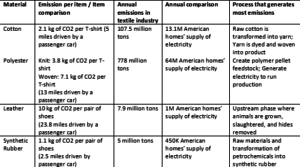

A 2009 report estimated that the global apparel industry consumed nearly 1 billion kWh of electricity or 130 million tons of coal.[3] Nike can focus on materials, since the company uses more than 16,000 materials products each year, one pair of shoes can have up to 30 materials, and the below 4 materials are found in 98% of its products.[4]

Chart 1: Carbon Emissions by Material[5]

Water Waste

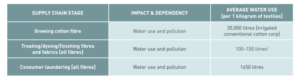

There will be an imbalance between the demand for new clothes and the supply of water to produce these clothes, with demand predicted to exceed supply by 40% in 2030. The 28 billion kilograms of textiles that are dyed per year require over 5 trillion liters of water (2 million Olympic-sized swimming pools). Furthermore, countries that are part of the textile supply chain, such as China, India, and Bangladesh, are already stressed by insufficient water supply.[6]

Chart 2: Water Waste by Stages[7]

Regulatory Risks

The COP21 Climate Agreement, effective in 2020 to address global warming, increases the risk that companies will be held to sustainability goals. [8]

Profitability Risks

Climate change results in extreme weather conditions that disrupt Nike’s supply chain. For example, in 2008, floods temporarily shut down four Nike factories in Thailand, and there is concern about droughts for cotton-producing regions.[9]

Similar to what happened in the food industry, customers are starting to care about whether their clothes were produced sustainably. Customers may choose to shop at companies that have incorporated sustainability practices into their business model.[10]

Nike: Steps Taken

Nike’s mission is to double the business while halving the impact.

Product/Materials

Nike focused on increasing sustainable materials, resulting in the greatest environmental impact in the entire product cycle. The Material Sustainability Index lets teams compare the environmental impacts of 57,000 materials across 741 vendors, resulting in 26% sustainable cotton and 17% recycled polyester. Flyknit technology has reduced waste by 60% and expanded into 28 products across 6 categories.

Carbon/Energy

Nike committed to decreasing its carbon footprint, especially during the high-impact, materials stage of the value chain: materials growing, processing, and finishing. In addition to using low-carbon materials, the company developed an energy-efficient resource toolkit for dyeing and finishing facilities to be rolled out in FY16/17. The company scaled renewable energy at its own factories, while encouraging manufacturers to decrease emissions. These actions resulted in an 18% per-unit reduction in CO2 emissions.

Waste

Nike reduced waste by designing better products from the start. Its Flyknit technology reduced waste by 2M pounds, and recycled polyester yarn diverted >182M plastic bottles from landfills. Nike used recycled materials in 71% of its footwear and apparel products, while encouraging material vendors to ship pre-cut pieces and recycle scraps at their own factories. The company achieved 6% per-unit savings across categories and reduced the shoebox weight by 6.3%.

Water

Nike collaborated with material vendors with water-intensive textile dyeing and finishing operations to help manage water and reduce waste. Nike was incentivized to work with suppliers since the latter’s performance was incorporated into Nike’s sustainability index. The ColorDry technology was used by a Taiwanese facility to dye fabrics without water, saving 20M liters of water. Results included an 18% per-unit water reduction in apparel, and a 43% per-unit water reduction in footwear manufacturing.[11]

Nike: Other Ideas

- Optimize logistics: While CO2 emissions per unit decreased, the overall energy use and CO2 emissions increased 14% from FY11 to 15 due to inbound logistics.[12] Nike should think of ways to optimize its logistics.

- Recycling Campaign: The company emphasizes re-use and recycling, evident in the Nike Grind program, which is a collection of premium recycled materials. However, there is no clear way for consumers to recycle products. Like H&M, which collects used clothing at its stores, Nike should create an effective recycling campaign.[13]

- Lead by Example: Nike has achieved significant savings and led the apparel industry in sustainability practices. They have encouraged partners to do the same, and now they should also galvanize other players to complete on sustainability.

Nike has shown that it’s possible to be both sustainable and successful in the apparel industry, developing technologies with the added complexity of sustainability. Nike should help other companies, work with its own suppliers, partners, and distributors, and keep innovating its technology and sustainability practices.

(796 words)

Abnett, Kate. “What the COP21 Climate Agreement Means for Fashion.” The Business of Fashion. Business of Fashion, 16 Dec. 2015. Web. 02 Nov. 2016.

Conca, James. “Making Climate Change Fashionable – The Garment Industry Takes On Global Warming.” Forbes. Forbes Magazine, 3 Dec. 2015. Web. 02 Nov. 2016.

Davenport, Coral. “Industry Awakens to Threat of Climate Change.” The New York Times, 23 Jan. 2014. Web. 2 Nov. 2016.

Kirchain, Randolph, Elsa Olivetti, T. Reed Miller, and Suzanne Greene. “Sustainable Apparel Materials.” Sustainable Apparel Materials (n.d.): n. pag. MIT Publication. MIT, 7 Oct. 2015. Web. 2 Nov. 2016.

Maxwell, D. McAndrew, L. Ryan, J. 2015, State of the Apparel Sector Report – Water a report for the global leadership award in sustainable apparel, aug 2015

Nike Sustainability Report FY14/15

[1] http://www.forbes.com/sites/jamesconca/2015/12/03/making-climate-change-fashionable-the-garment-industry-takes-on-global-warming/#41f9d9ff778a

[2] http://msl.mit.edu/publications/SustainableApparelMaterials.pdf

[3] http://msl.mit.edu/publications/SustainableApparelMaterials.pdf

[4] Nike Sustainability Report FY14/15

[5] http://msl.mit.edu/publications/SustainableApparelMaterials.pdf

[6] http://glasaaward.org/wp-content/uploads/sites/4/2015/05/GLASA_2015_StateofApparelSector_SpecialReport_Water_150624.pdf

[7] http://glasaaward.org/wp-content/uploads/sites/4/2015/05/GLASA_2015_StateofApparelSector_SpecialReport_Water_150624.pdf

[8] https://www.businessoffashion.com/articles/intelligence/what-the-cop21-climate-agreement-means-for-fashion

[9] http://www.nytimes.com/2014/01/24/science/earth/threat-to-bottom-line-spurs-action-on-climate.html?_r=0

[10] http://www.forbes.com/sites/jamesconca/2015/12/03/making-climate-change-fashionable-the-garment-industry-takes-on-global-warming/#5fd485c8778a

[11] Nike Sustainability Report for FY14/15

[12] Nike Sustainability Report for FY14/15

[13] https://www.businessoffashion.com/articles/intelligence/what-the-cop21-climate-agreement-means-for-fashion

The most interesting part of the post to me is the carbon emissions by materials section. Knowing this information, Nike should both investigate how to reduce amount of material used per article of clothing and how to shift its products to be made from low energy intensive materials (synthetic rubber, cotton, etc). It seems like Nike is already heading towards the right direction by committing to minimize waste by 5% in key business operations and 10% reduction in its product environmental footprint (http://s3.amazonaws.com/nikeinc/assets/56356/NIKE_FY14-15_Sustainable_Business_Report.pdf).

I also agree that a recycling campaign could be another way that Nike can implement to make a difference. H&M gives a discount to customers who bring in used clothing and the incentive minimize the friction for customers. Nike could employ a similar strategy.

Thank you for this well-written and interesting post. It seems like Nike is doing a great job of trying to mitigate its impact on climate change. Having said that from my personal consumer experience I think they could be going one step further by communicating some of these achievements more prominently to their customers. For their Earthkeeper series of products, Timberland has not only used recycled materials in its products, used 100% of renewable energy in its factories and planted hundreds of trees to off-set carbon emissions from its supply chain, it has also very prominently included information on the climate impact the specific products had overall. This Green Index was featured on boxes or small flyers attached to the products and detailed the climate impact, the chemicals used, and their resource consumption for the various products. Now you can actually look up the Green Index for all Timberland products and inform your buying decision on this basis. I think this type of transparency and consumer education is necessary to not only tackle climate change from the supply side, but also improve it from the demand side.

Here is an article about the index:

https://www.greenbiz.com/news/2010/08/16/timberland-expands-its-green-product-rating-embraces-eco-index

Very interesting to analyze the sustainability strategy for a company that we all know and love!

It seems like Nike is taking a comprehensive and serious approach to sustainability, which is critical given their visibility in the retail market. Recently, Nike has faced issues with its supply-chain with delayed orders and stock-outs. In August of this year, Nike formed a partnership with Apollo (private equity firm) to purchase a couple of suppliers, leading to a more vertically integrated approach for Nike. I would be interested to know to what extent, if any, these supply-chain issues were due to sustainability factors?

http://www.wsj.com/articles/nike-forms-supply-chain-pact-with-apollo-1471559736

In 2012, Nike purchased a minority stake in a Llamasoft, a provider of sustainable and efficient supply chain solutions. Part of this investment was to ensure Nike had both economically and environmentally friendly supply chain practices. Do you think the root cause of the recent supply-chain inefficiencies could be due to sustainability requirements? How efficiently is Nike balancing sustainable practices with efficiency and cost, since these concepts are often at odds?

http://news.nike.com/news/nike-partners-with-llamasoft-for-sustainable-supply-chain-innovation