Shooting for Mars: How Startup Relativity Space Is Using 3D Printing to Go Intergalactic

A look into startup Relativity Space and its use of 3D printing for the development of space-bound rockets.

Multi-planetary human inhabitance. What on Earth does that even mean? Simply put, it refers to humans living on various planets. For now, Mars seems to be the most viable alternative option for human living. Scientific findings suggest that there is potential for humans to live on Mars within the next 15 to 20 years.1

A lot of questions are swirling about how this reimagined reality could be possible. Air, climate and sustenance are just a few of the question-generating topic areas. A fairly simple question, though, is yielding significant buzz – how does one get to Mars? There are exploratory projects committed to answering this query.

Fairly predictably, the National Aeronautics and Space Administration (NASA) has launched related initiatives, but as a government agency, funding is highly debated. The space exploration necessary would cost NASA hundreds of billions of dollars, and constituents’ stance on such spending varies widely.1 Though similarly challenged by the underlying question at hand, private ventures are able to circumvent some of this contention.

Cue Relativity Space. Relativity is a private orbital launch startup currently focused on sending small weather-tracking, Earth-snapshotting, internet-transmitting satellites into low Earth orbit.2 It has raised more than $45 million in venture capital, garnering support from Social Capital, Y Combinator, and Mark Cuban.3 Founders Jordan Noone and Tim Ellis are redefining the design and manufacturing of rockets, an identified mode of space transportation.

The process is uniquely centered around additive manufacturing, also known as 3D printing.3 Companies like Elon Musk’s SpaceX and Jeff Bezos’ Blue Origin have incorporated non-traditional manufacturing, but not to the extent of Relativity, which aims to 3D print at least 95% of its first midsize rocket Terran 1, currently scheduled to launch in 2020.4

Relativity ultimately intends to go beyond low Earth orbit and land the first wholly 3D printed rocket on Mars. Most ambitiously, Noone and Ellis envision sending 3D printers to Mars and other off-world colonies to help build the infrastructure necessary for sustaining human life.2 This objective is arguably akin to a proverbial mic drop. Relativity is making great strides toward this future state, with additive manufacturing serving as its competitive edge.

In the last 10 years, at least 15 to 20 rocket companies have been founded, all vying for a slice of limited space travel pie.3 Relativity is indeed contending in space race 2.0. To formidably meet competitive forces, specifically companies who have already completed initial rocket test launches, the startup is doubling down on simplified design and 3D printing.2

Most rockets consist of roughly 100,000 individual parts, but Terran’s design will incorporate fewer than 1,000.2 In tandem with 3D printing, Relativity maintains it will be able to condense the rocket development cycle from the 24-48 months typically required to roughly 60 days.4 This time improvement is largely attributed to additive manufacturing, which allows for swift design iterations relative to traditional, tool-intensive processes.

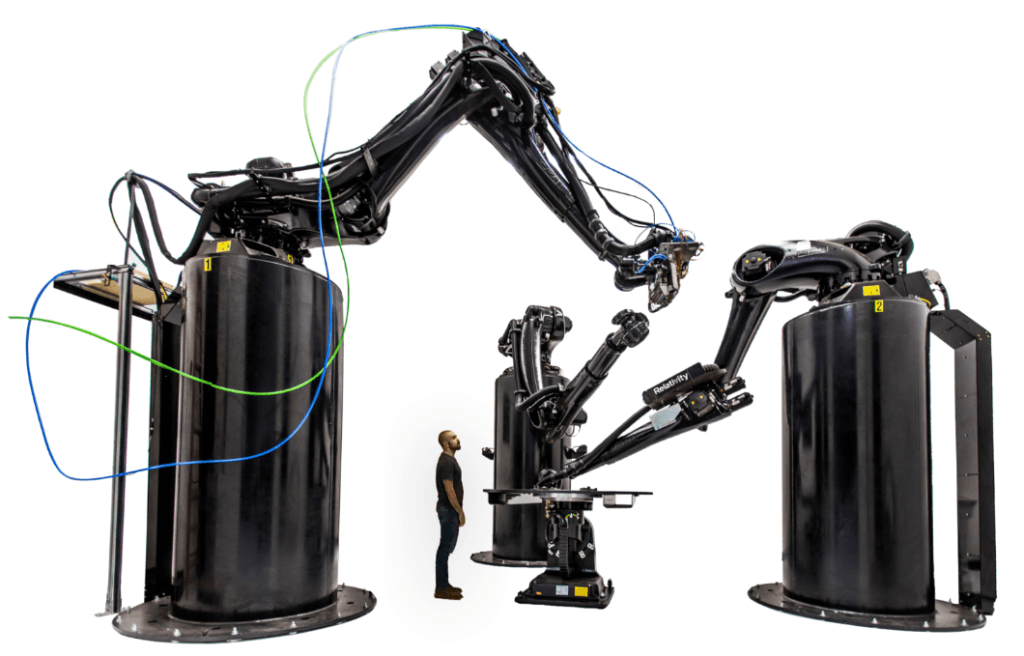

Proactively, the startup has built Stargate, the world’s largest, 24-foot 3D metal printer.3 The printer uses sensors and function-based learning to print rockets faster, and in turn, cheaper.4 While rapid rocket design and production is critical in the near term, in the medium to long term, rocket testing is especially imperative. Relativity has thus entered a 20-year partnership agreement with NASA’s Stennis Space Center in Mississippi to test its rocket engines.2

Product development in the aerospace realm is extraordinarily complex. Relativity is wise to first enter the niche, small-size satellite arena before ratcheting up to larger satellites or space tourism. The startup, however, is in a capital-intensive business, up against more established space companies. Despite having efficient design and additive manufacturing on its side, Relativity has some catching up to do.

For instance, there is fundamental skepticism regarding the durability of a large 3D printed structure.3 The company should expand its partnerships with seasoned aerospace sector incumbents, both public and private, to propel testing efforts forward and achieve a timely Mars landing. Pressure testing prototypes early and often is the name of this game. The risk of intellectual property exposure is real, but so is the outright dominance of the market by even technologically-inferior players who are simply well-funded.

Moreover, Relativity appears to be strictly focused on its small satellites, limiting experimentation related to its lofty future goals and product demands. There is potentially an opportunity to engage in more aggressive, in-parallel product development. Human capital bandwidth constraints are likely widespread at this startup, but this limitation could also be addressed through strategic partnerships.

Alas, it seems like it will take a few years before otherworldly living becomes an option for humans. How will Relativity fare among the likes of NASA, SpaceX and Blue Origin? Is 3D printing a sufficiently secret sauce? Time will soon tell.

(784 words)

Endnotes

[1] Brooke Ross, “Mission to Mars,” Junior Scholastic, vol. 118, no. 9, February 29, 2016, via EBSCOhost, http://ezp-prod1.hul.harvard.edu/login?url=http://search.ebscohost.com/login.aspx?direct=true&db=f5h&AN=113242386&site=ehost-live&scope=site, accessed November 2018.

[2] Jennifer Johnson, “Rocket Plan: How 3-D Printing Is Unlocking A New Space Race,” Forbes, May 16, 2018, https://www.forbes.com/sites/jenniferjohnson/2018/05/16/rocket-plan-how-3-d-printing-is-unlocking-a-new-space-race/#64aef7de66bf, accessed November 2018.

[3] Samantha Masunaga, “Entrepreneur seeks to boldly go where no one has gone before: 3-D printing nearly an entire rocket,” Los Angeles Times, April 27, 2018, http://www.latimes.com/business/la-fi-rocket-tim-ellis-relativity-20180427-story.html, accessed November 2018.

[4] Apekshita Varshney, “Relativity Space Is 3D Printing An Entire Rocket,” Techweek, September 10, 2018, https://techweek.com/relativity-space-is-3d-printing-an-entire-rocket/, accessed November 2018.

[5] Relativity Space, https://www.relativityspace.com/, accessed November 2018.

Thanks for sharing!

Relativity Space was the first to successfully 3D print a full-scale aerospace quality fuel tank, measuring 7 feet in diameter and 14 feet in height over. The process took 7 days of print time, though longer to develop and test their design. Normally to order and receive a tank of that size and quality would take over twelve months [1]. With this technology already in hand, will Relativity Space’s Stargate become the key to unlocking additive manufacturing for large parts? Should they produce more Stargates, reap the profits, and aid other companies to manufacture bulky items? Or is it in their best interest to keep the technology private?

[1] “Ep 8 Printing Tomorrow/Are We Alone?” HBO NOW®, VICE, play.hbonow.com/episode/urn:hbo:episode:GWtT0DQrkjri8vQEAAABT?_ga=2.84976285.588078005.1539732024-100924822.1537398855.

This is probably one of the coolest things that anyone on earth is trying to do right now. If they are able to figure out the technology for 3D printing a rocket that can get to Mars, could they put a remotely operated 3D printer on Mars as well? A large part of the problem with humans living off-planet is the impossible difficulty in building a habitat fit for humans – if we could have robots build it for us first, the future may have officially arrived.

Thank you, this was very interesting article! Given that this is new technology and it was not tested by years of sending spaceships to the moon, so I assume that safety concerns will be high, as well as how safe and durable as you have mentioned the prototypes will be. This might also entail regulation scrutiny on behalf of NASA / government. So the biggest chunk of the time saved on prototyping can be eaten up by bureaucracy and getting the right paperwork.Is there a way how you can mitigate this issue?

Very interesting, thank you! You mention the risk of intellectual property disclosure in the article. Would you consider Relativity’s primary strength to be the size of it’s additive manufacturing machinery or it’s powers of efficient design? In either case, is it not very simple for better-funded competitors to mimic their approach (without breaching any patents etc), thereby removing Relativity’s competitive advantage? With the number of highly talented minds in the space company space, it seems a particularly difficult environment for a startup to operate in. Do you have any sense of whether they are just waiting to be acquired by a bigger player?