Running on Fumes

In the beginning of May, a small company called Ingevity spun off of WestRock, the packaging conglomerate formed from the merger of MeadWestvaco and RockTenn. This division of WestRock was a curious little engineering group that was responsible for what essentially amounted to recycling the byproducts of packaging production. Their performance chemicals group transformed crude tall oil (the sap produced when turning trees into paper) into high value derivative products such as pavement, lubricants, inks, along with other products that were traditionally manufactured with crude oil. However, it is the performance materials group and their proprietary method of manufacturing activated charcoal that developed technology which now recovers 3.7 million gallons of gasoline per day that would otherwise escape into the atmosphere. [1]

In the 1970s, Ingevity’s engineering team was grappling with what to do with the enormous quantities of hardwood sawdust they were producing as they turned trees into paper. The developed and patented a method for producing sulfur activated charcoal, a process involving extremely hot sulfuric acid which created a type of activated charcoal with a significantly higher butane working capacity (BWC) than traditional thermal activated charcoal. The company discovered that this new charcoal was very effective at capturing gasoline fumes. They also discovered that when they ran air through a piece of charcoal that was soaked with gasoline fumes, pure gasoline came out the other side. They took this charcoal and fitted it into containers and placed them between the gasoline tank and the engine of a car. When the car was parked, the gasoline would slowly evaporate and fill up the charcoal. The next time the car was turned on and driven, airflow would move through the charcoal, converting the fumes back into gasoline and forcing them into the engine, reducing the loss from a single day of parking. [2]

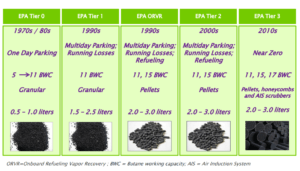

Over the subsequent decades, Ingevity continued to improve on their product and design, ultimately creating a honeycomb structure known as a monolith which had a BWC of 17. In the below chart, you can see the evolution of their sulfur activated charcoal offering.

As Ingevity developed activated carbon solutions with higher BWCs, the regulators took heed and incorporated these products into the regulation. Ingevity was actually able to improve the speed at which the regulations increased their demands by providing products around which the regulators could construct legislation.

Today, in an age where preventing climate change is more important than ever, the innovation that Ingevity committed itself to in the 70s appears to be an investment that returned well beyond its expectations. Not only is Ingevity the leading producer in the world of automotive activated carbon, they are the only player in gasoline emissions loss control devices. Though conveniently left off of their company slides and SEC filings as to avoid attention, Ingevity is the only company automobile manufacturers trust when it comes to these devices for their cars. Looking at the recent Volkswagon emissions scandal, we can see why OEMs are not willing to take a risk with a new and unproven manufacturer over a device which costs under $50 per vehicle.

This project that began primarily for the North American market has become the standard worldwide for gasoline emissions. We see this through the ongoing development of regulation in Europe and China. Euro 6 [4] and China 6 [5] are two new pieces of regulation that adopt very high standards and take the highest US standards (LEV) [6] and apply them in different regions. It would not be possible to enforce these regulations without multi-decade innovative project at Ingevity that created these emission loss control devices.

The trend of adopting the state of the art technology to rapidly address the growing concern of climate change is something that is likely to continue for many decades and this will be a tailwind in Ingevity’s sails. As the current pieces of regulation (China 5 and Euro 5) continue to be adopted, we can expect to see Ingevity’s dollar share per car worldwide increase as the technology is incorporated beyond North America. Ingevity has anticipated this and recently constructed two new factories in China to satisfy this demand.

Going forwards, Ingevity needs to develop a plan for what to do as consumers shift to electric vehicles. Ingevity should work on developing a solution for capturing escaping fuel during the energy production process in plants. While we may not continue to burn gasoline in our cars, we will likely continue to have fossil fuels somewhere in the energy process for many more decades. They have not yet approached this because they have not yet felt the need; however, going forwards, they are likely to face pressure from the shift in consumer demand.

Word Count: 781

- Ingevity Form 10-12B/A, 4/22/16.

- Ingevity Investor Day Presentation 4/26/16 p. 26.

- Ibid p. 27.

-

“Cars and Light Trucks.” Emission Standards: Europe:. N.p., n.d. Web. 04 Nov. 2016.

-

“China: Cars and Light Trucks.” Emission Standards:. N.p., n.d. Web. 04 Nov. 2016.

-

“Cars and Light-Duty Trucks-California.” Emission Standards: USA:. N.p., n.d. Web. 04 Nov. 2016.

Interesting topic.

A relevant follow up question is if the technology can be applied to diesel fuel as well. If so, the product may have a longer life within heavy equipment/heavy transport as these industries are lagging the car industry in terms of the migration to battery technology. For example, Hitachi, a global heavy machinery manufacturer, offers only one model of their heavy machinery completely powered by a Lithium battery.[1]

[1] http://www.hitachi-c-m.com/global/environment/showcase/battery.html

It is interesting to see an example of a company that is having a very positive impact in society without aiming explicitly to do so. From what I understand they have been able to grow at incredible rates and maintain market leadership just by offering a product that delivers great value to the user (less leakage) rather than because they sell a sustainable product that hipsters might be attracted to.

This is a way for supporting sustainability is often deprioritized because it does not grant the same PR as CSR. My hypothesis is: in the future, having a product that promotes sustainable practices on top excelling at its core functionalities, will prove to be an edge given the current paranoia around climate change.

It also great to see that this company will keep having enormous growth due to new regulations coming into place all over the world. It just leaves me wondering whether this won’t attract new competition; if the company should put strategic measures in place to develop new products; and whether those new products could properly compete if they lack the amazing impact that the carbon filters provide, given that sustainability is more of a concern now.

Interesting product! I agree Ingevity should look for new applications to activated charcoal as the proliferation of electric vehicles rises in developed markets. Activated charcoal has many uses, and I think water purification is especially relevant to climate change and the environment. Nearly 700 million people do not have access to reliable, clean drinking water [1]. Additionally, climate change will likely reduce the availability of clean freshwater. For instance, the 2012 Washington State Integrated Response Strategy for Climate Change assesses a decline in water quality will occur due to saltwater intrusion and increased storm runoffs [2].

1. World Health Organization and UNICEF Joint Monitoring Programme. 2015. Progress on Sanitation and Drinking Water, 2015 Update and MDG Assessment

2.Adelsman, H., and J. Ekrem. 2012. Preparing for a changing climate: Washington State’s Integrated Climate Response Strategy.

This was a fascinating post on a compelling industrial niche that I knew very little about. Daniel, I particularly appreciated how you pulled back in your last few paragraphs to raise some of the key questions facing Ingevity in the decades to come. There is a significant irony at play that makes for a fascinating dynamic: Ingevity is an example of a company that has and will continue to ride the wave of incremental adoption of more climate friendly solutions– yet, their business model is directly threatened by a disruptive leap forward (electric vehicles). I completely agree with your assertion that they need to diversify into other technological applications; it would be a real tragedy to see this company devolve from a forward-thinking, environmentally innovative company into an organization that combats more substantial progress because it undermines their current business model. Said simply, Ingevity should innovate with its business model rather than lose its place high atop the list of climate-friendly innovators.

Thanks for the insightful article, Daniel. I definitely had not heard of this company nor the technology that they employ. It is very clear that industry standards coupled with national regulations has been in favor of this company. I would normally think that this would be a hurdle for such an innovative technology that they sell, to not have the buy-in from the automobile industry and across countries/regions at that.

I definitely support your argument that an innovative move and new market share capture would be for the company to create a similar technology for electric cars given the growth of these products. Naturally the car industry will begin to shift more to electric vehicles or at least to vehicles using alternative fuels. I am most curious about Ingevity’s own internal manufacturing and production processes. You briefly allude to this in your piece, but it would only be doing justice to the field for Ingevity to invest research and development to capturing escaping fuel from the energy production process in plants, starting with their own.