More with less at Nike

Nike has declared war on climate change, but to win they must focus more on materials innovation than in the past

“We know efficiency is not enough. The world needs systematic change at scale. We must innovate.” – FY14/15 Nike Sustainable Business Report

True to their popular marketing slogan “JUST DO IT.”, Nike has chosen to address climate change head on by proclaiming in early 2016 that their ambition is to double their business, with half the environmental impact. This implies $50 billion in revenue along with meeting various other sustainability targets by 2020 (1). Nike is already a market leader in sports apparel and footwear. Why have they committed to such a lofty goal? Is it really possible to do “more with less” to this extent?

The recent adoption of the Paris Agreement in late 2015 (2) serves as a positive indicator that policy makers are serious about climate change regulation. The need to reduce greenhouse gas emissions and reduce the environmental impact of human activity is recognized across the public and private sectors. As an example, the Paris Agreement stipulates regulations that will hold the increase of the global average temperature to well under 2 degree Celsius above pre-industrial levels (3). These types of changes would have a significant impact on Nike, a company that has resource-intensive manufacturing operations at 666 factories in over 40 countries (4).

Exhibit 1 (5)

Nike has chosen to get in front of regulation and scrutiny by committing to their aggressive sustainability targets. Halving of their environmental footprint depicted above while doubling sales will require significant changes in the way Nike thinks about transparency across their supply chain, innovation models and product development metrics. To this end, they are taking some critical steps (8):

- Increasing transparency and sustainability of factory operations and locations. Nike has released to the public the details and locations of all its factories worldwide to reduce non-compliant practices (leveraging the public and NGOs as watchdogs). It has also committed to only source from factories that meet their definition of sustainable (“Bronze” or better rating on their Sustainable Manufacturing and Sourcing Index) by 2020 (6).

- Leveraging partners in an open innovation model. In 2015, Nike entered a partnership with MIT to drive materials innovations that break the tradeoffs between costs, end-use performance attributes and environmental impact (7). This is an uncharacteristic pre-competitive investment by Nike as they leverage crowd sourcing across the industry to find new solutions. They also developed a free mobile app called MAKING that is designed to help designers make better materials decisions by providing environmental impact and resource intensity data.

- Instituting sustainability metrics in the product development process. Sustainability scores and indexes are used to help encourage the use of more sustainable materials and reduce waste by improving pattern efficiency. Nike has introduced their Materials Sustainability Index which contributes to a composite score for each manufactured product that considers the complete environmental profile. These scores and indexes are used to inform better material and design choices with no sacrifice to functionality.

Despite these efforts, there is still a significant amount of work to do especially in regards to materials innovation.

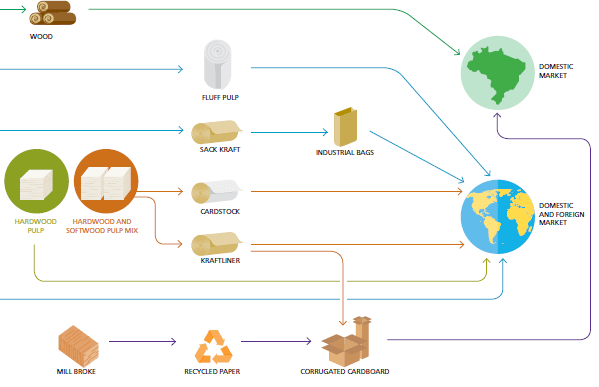

Exhibit 2 (9)

Raw materials and materials manufacturing has by far the greatest impact on Nike’s usage of water and energy along with being the biggest contributor to greenhouse gas emissions (Exhibit 2). The answer to how to do “more with less” will necessarily involve innovations in the types of materials used in Nike’s products. The company has already taken steps toward an open innovation model where they are partnering with research institutions and other industry players. However, as the future depends on innovations such as Nike FlyKnit and Grind (premium raw materials derived from recycled shoes a la circular economy), there will need to be a fundamental shift in the people and processes at the company.

In the past, product design and materials R&D have been decoupled with one team optimizing for product performance and aesthetics through design and the latter focusing on developing new materials optimized for certain performance characteristics. Product designers would essentially pick materials from a menu that best met their needs. Now, as Nike has begun to implement sustainability metrics into their material choices and product designs, there is greater transparency to the tradeoffs that designers are making between functional performance and environmental impact. To ensure that the company continues to deliver superior product performance, it must not only drive product innovation but materials innovation as well. This requires hiring more materials scientists, changing the composition of product teams to include more engineers and scientists and partnering with materials companies from the onset of the product development process. The metrics Nike has implemented must be iterated on to ensure that they are appropriately informing design choices. Measuring is one thing, but effectively determining when to choose sustainability over increased performance and vice versa in specific instances will be critical.

(799 words)

References:

- FY14/15 Nike, Inc. Sustainable Business Report.

- Adoption of the Paris Agreement, United Nations Framework Convention on Climate Change, https://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf, accessed November 2016.

- Ibid.

- Nike Manufacturing Map, http://manufacturingmap.nikeinc.com/, accessed November 2016.

- FY14/15 Nike, Inc. Sustainable Business Report.

- Ibid.

- “MIT Climate CoLab and Nike call for materials innovation to combat climate change,” press release, September 25, 2015, Nike website, http://news.nike.com/news/nike-inc-and-mit-climate-colab-materials-innovation-to-combat-climate-change, accessed November 2016.

- FY14/15 Nike, Inc. Sustainable Business Report.

- Ibid.

Thank you for the fascinating article. It is interesting to hear about some of the actions that a leading consumer goods firm is taking in order to respond to climate change.

I’m interested that Nike is prioritising the materials innovation aspect of it’s environmental impact, particularly in the context of their value chain footprint. Nike has made sensible first steps by opening up it’s innovation funnel through the relationship that it has engaged in with MIT, representative of the need of many consumer firms to look outwards to source the capabilities to address the challenges of climate change, and in particular materials challenges that they are facing.

Nike has opportunities to show it is committed to its intention and to scale up the ambition of its plans. As touched on, Nike will reveal it is committed to its intention when it is faced with trade-off decisions. Is Nike willing to trade-off profit, or performance (e.g. colouring of their shoes) and pay higher prices for sustainable materials? These are not easy decisions, but will likely have to be made at some stage. If Nike is willing to do so, it will communicate clearly that it is committed to sustainability.

Further, I would argue that given materials innovation will take time, in the short term Nike has an opportunity to look towards the end of its value chain to minimise footprint. A large share of Nike’s footprint falls in ‘consumer use’ and ‘end of life’. Scope therefore exists for Nike to establish collection schemes and to educate the user on the disposal of their products.

Thanks for providing some of the ways that Nike has been able to move towards a more sustainable future. I would be curious to see how much Nike has invested in developing technology to recycle old clothing and apparel into new clothing. I know that in many of their stores they have drop boxes, for customers to recycle their old sneakers, but I would like to know if they also recycle old apparel? One of the biggest sustainability problems with the apparel industry is that in the past decade, the periodicity with which new products are released has decreased from multiple months to mere weeks. As companies, like Nike, look to drive their revenues higher, they release more and more clothing. This not only creates an attitude of wastefulness among customers, but also causes a glut of inventory that Nike sells off in outlets. Even when consumers donate their clothing, the clothing rarely ends up being reused. Instead, it is often shipped in bales to emerging nations where the majority of the clothes in the bale then get dumped. While apparel recycling could alleviated some of this problem, it ultimately does not solve the underlying issue. If Nike was truly dedicated to sustainability, then they would rethink the way in which they sell apparel and shoes to customers.

Andrew, thanks for the insight.

Nike’s position as the 18th most valuable brand (as learned in MKT) is surely a key point of leverage that it must maximise as it develops its stance on sustainability. This should lead to a two-fold impact – driving sustainable innovation up and down its supply chain; and encouraging its consumers to be more thoughtful as they use and dispose of Nike products.