Military Technology, Conflict Minerals, and the Risks of International Segmentation

How a defense technology giant is bearing the weight of political, legal, and ethical pressures to cleanse its global supply chain.

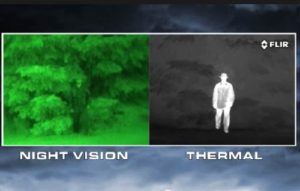

Seeing the Unseen

FLIR Systems is a leader in developing technologies that “enhance perception and awareness.” Founded in 1978, FLIR designs, develops, markets, and distributes a product suite that ranges from consumer thermal cameras to night vision and aircraft-mounted imaging systems for military use. Although FLIR is headquartered in the United States, they have locations spanning across the world, including Israel, the UAE, India, and China. Accordingly, FLIR’s global supply chain is fragmented; the core of many of FLIR’s products is an infrared camera sensor, which is produced in California and transported to FLIR facilities across the world. The thousands of other components needed by FLIR to manufacture its products are procured as complete assemblies or components from various suppliers [1].

Trust Issues

The international segmentation of FLIR’s supply chain has resulted in various roadblocks, including compliance with international laws and standards governing trade. In accordance with the California Transparency in Supply Chain Act, large manufacturers, such as FLIR’s Santa Barbara facility, are required to disclose their efforts to eradicate slavery within their supply chains [2]. There is concern that some raw material inputs for FLIR’s finished goods are sourced from the Democratic Republic of Congo (DRC), and are thereby “conflict minerals” (CMs) [3]. Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act directs the Securities and Exchange Commission (SEC) to promulgate restrictions that require public companies to disclose their use of such minerals, as these CMs directly benefit armed groups in the DRC [4]. In accordance with United Nations due diligence guidelines, FLIR is obligated to take proactive measures to minimize the usage of CMs [5].

Additionally, because FLIR produces a core component of their products in the US (infrared camera sensor) and then exports it to manufacturing locations across the globe, there is a complex regulatory framework that limits its ability to distribute this sensitive technology. Per an interview with an attorney who specializes in international trade and import/export controls, such military technologies are controlled for export under the International Traffic in Arms Regulations, a United States regulatory regime [6]. For these exports, a license must be procured from the US State Department‘s Directorate of Defense Trade Controls via a lengthy and costly process. These licenses strictly limit the partners to whom the product may be distributed (no use of third party distributors unless specifically authorized) and place a cap on the quantity that may be exported over a defined time period [7].

Incremental Solutions

FLIR has taken measures to address these various concerns in the short term. With regards to its usage of conflict minerals, FLIR has distributed its supplier code of conduct in multiple languages, in which FLIR specifies labor condition requirements and emphasizes compliance with the Conflict Minerals Act [8]. FLIR has also created and distributed a standard questionnaire that requires each supplier to self-certify that it does not engage in illegal activities. FLIR has attempted to comply with UN Due Diligence guidelines for its supply chain via the establishment of dedicated internal managerial systems and cross-referencing of smelter and refiner information with data from the Conflict Free Smelter Program [9]. The success of these measures has been limited to date, primarily due to limited supplier completion of surveys.

In the medium term, FLIR is attempting to vertically integrate its supply chain to circumvent the above issues and maximize its control of raw material sourcing [1]. FLIR is also expanding its utilization of lean techniques, point-of-use material replenishment, and value-stream mapping. Regarding risk mitigation, FLIR plans to develop a policy to escalate senior management’s involvement with non-compliant suppliers and begin requiring supplier remediation of issues so that they are compliant with FLIR’s policies on conflict minerals and security [8].

Recommendations

To maximize control over its supply chain, FLIR should take responsible measures. Independent third-party audits of supply chain due diligence would help minimize the use of CMs. These audits should be unannounced and randomized. Moreover, FLIR should have all supply chain members sign contracts that affirm their commitment to legal and ethical labor, raw material sourcing practices, and compliance with U.S. export regulations by enforcing their own due diligence procedures. FLIR should minimize the involvement of other parties in their supply chain and employ the industry best practice of utilizing third party services to screen potential customers and distributors against “denied parties” lists produced and enforced by the US government. Through these measures, FLIR will be more compliant with international trade laws.

What’s Next?

Going forward, FLIR’s ability to maintain a legal and ethical international supply chain is unclear. Will FLIR be able to establish enough transparency to reasonably prevent the usage of conflict minerals? How will shifting US international trade policies under the Trump Administration impact FLIR’s ability to export sensitive technology? The answers to these questions remain invisible.

(800 words)

References

[1] Gager, R. “FLIR Systems Inc.” Supply Chain World. 2015 March 26. [http://www.scw-mag.com/sections/retail/433-flir-systems-inc], accessed November 2017.

[2] State of California Department of Justice. “California Transparency in Supply Chains Act, SB 657.” 2010 September 30, [https://oag.ca.gov/SB657], accessed November 2017.

[3] FLIR Systems. “United States Securities and Exchange Commission Form SD Specialized Disclosure Report.” 31 May 2016, [http://www.flir.com/uploadedFiles/Corporate/FLIR%20-%20Form%20SD%20[Executed]_(palib2_8074700_4).pdf], accessed November 2017.

[4] Business for Social Responsibility. “Going Beyond the Supply Chain in the Democratic Republic of Congo.” February 2012, [https://www.bsr.org/reports/BSR_Interim_Report_Going_Beyond_the_Supply_Chain.pdf], accessed November 2017.

[5] United Nations Security Council. “Due diligence guidelines for the responsible supply chain of minerals from red flag locations to mitigate the risk of providing direct or indirect support for conflict in the eastern part of the Democratic Republic of the Congo.” 30 November 2009, [https://www.un.org/sc/suborg/sites/www.un.org.sc.suborg/files/due_diligence_guidelines.pdf], accessed November 2017.

[6] International Traffic in Arms Regulations. “22 C.F.R. Parts 120-130.” 6 November 2017, [https://www.pmddtc.state.gov/regulations_laws/itar.html], accessed November 2017.

[7] Interview with legal professional (name protected for anonymity and client-attorney privilege), November 2017.

[8] FLIR Systems. “FLIR Supplier Code of Conduct.” 8 November 2016, [http://www.flir.com/Documents/Supplier/FLIR-Supplier-Code-of-Conduct.pdf], accessed November 2017.

[9] Organisation for Economic Co-operation and Development. “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas.” 2013, [https://www.oecd.org/corporate/mne/GuidanceEdition2.pdf], accessed November 2017.

Although the Dodd-Frank legislation and follow-on SEC regulations require transparency of supply chains for any conflict minerals, there is no regulation restricting its use. My recommendation to FLIR would go one step further and only source raw materials from a certified conflict-free source. The International Conference on the Great Lakes Region (ICGLR) provides a certification mechanism of conflict-free mineral chains (see http://www.oecd.org). To become certified, a third party audit occurs to ensure the mine is conflict free and complies with international laws, but also ensures there is proper chain of custody of the material from the point of extraction to the point of export. FLIR should move to this requirement for all of its suppliers, to decrease the risk of relying on self-report measures and to increase its commitment to improving the local communities near its sourcing of raw materials and to ensure compliance with the law.

Hey Damir! I actually have purchased and used a number of FLIR cameras.

First, I can back that there is significant pressure from the US government to get FLIR to stop exporting the technology. They have a unique camera that is very useful, and would love to have it exclusively.

I like your suggestion to fully audit the supply chain. This actually will also help with their State Department bid. If they have better control of their supply chain with full documentation, they can guarantee the authenticity of their items which makes the US Government happier.

Damir – This is a very interesting summary! I am a bit skeptical that having supply chain members sign contracts to affirm commitment to legal and ethical labor, raw material sourcing practices, and compliance with U.S. export regulations will actually result in improved outcomes or fewer compliance issues. This strategy is a relatively passive one, because it doesn’t allow FLIR to detect problems as soon as they arise. FLIR should take a more active role in finding compliance issues. This may involve helping supply chain members build their own capabilities to manage compliance issues.

This post reminded me of the challenges faced by United Interconnect, wherein their use of third party suppliers for their machinery resulted in information leakage of their proprietary design and technology. The solution we had identified then was to bring all this development in house, which it seems like FLIR is trying to do by vertically integrating its supply chain. Given the sensitive nature of FLIR’s offering – military product is certainly quite different from interconnectors! – I wonder how and to what extent FLIR should vertically integrate to protect its competitive edge. Should they prioritize vertical integration for their military-oriented products, or across the organization as a whole? What points in the supply chain should FLIR bring in-house, and how does this impact the ultimate cost of manufacturing their product?

Great article, Damir – thank you for sharing. This is an industry that I was not previously familiar with, and you convinced me that isolationism is a major issue for FLIR.

I do wonder if there are ways that FLIR can incentivize their supply chain partners to cooperate with their sensitivity efforts. In addition to the “stick” of audits, regulations and requiring contracts that you mention, can FLIR develop “carrots” that will mutually benefit both their own enterprise and those of their suppliers? I suspect that aligning incentives may result in better outcomes and scale that will help the whole supply chain generate more revenue by distributing their products more broadly.

Damir, I learned a lot from this post. I was particularly excited to learn about Section 1502 of the Dodd-Frank Wall Street Reform- I didn’t know that the SEC looked at public company’s use of CMs. I had previously assumed that change in business’s supply chains on these ethical issues were tied to customer demands, similar to how consumer preference for conflict-free engagement rings disrupted the market. Upon further research, I noticed that the regulation just requires disclosure vs. actually banning the use of conflict minerals [1]. This made me more impressed by FLIR’s commitment to UN standards as well as vertical integration of supply chain as it wasn’t officially required. I agree wth you that they need to involve third parties who can provide a more unbiased review and help the FLIR clean up its supply chain. Overall, this reminded me a lot of our Ikea case where a company can commit to higher standards due to its values even if financial metrics are impacted in the short-term. I look forward to tracking this company and hope that it becomes a standard for other players in the industry!

[1] https://hbr.org/2015/12/how-rfid-technology-improves-hospital-care

Damir, wow this is a difficult topic to address! Good job picking something which requires deeper thinking and is still an outstanding issue. While reading your essay, I also started thinking about the first question you ask on whether FLIR can establish enough transparency. Getting reports from its suppliers on “self-certification” or writing a code of standards, but seem like “check-the-box” items rather than substantive. Such reports can easily be fraudulent. After trying to think hard on this, I resorted to Googling to see if anyone else has solved the problem, and found the Engadget article below – which basically suggests: Technology has not been able to solve this problem, but there are interesting ideas people are trying out!

A few interesting solutions proposed are: Use RFID tags, collect information from suppliers, use blockchain. But it seems that the effectiveness of these solutions is still to be proven. Other solutions which are recently getting attention are: Using satellite imaging, or even better – a less “techy” solution which is to enable workers to anonymously provide information about their factories, or engaging NGOs/journalists and giving them access to data.

I could see how some of these solutions could be interesting for FLIR, particularly the low-tech ones; but quite frankly, I don’t have a good answer (and I don’t think the world does either) on how to solve this issue. Technology is only a tool/enabler; it will require deep thinking, experimentation, engaging people, and a lot of humanity to address this.

https://www.engadget.com/2017/07/31/technology-supply-chain-transparency/

Great article! I wonder given the various aviation and military applications of FLIR Systems’ products, that the various governmental clients may prefer less rather than more transparency regarding FLIR Systems’ supply chain. Reducing visibility as to the vendors, suppliers, raw materials, etc. may be preferential in order to mitigate risk against disruptors/saboteurs considering the product applications to aviation, national security, etc.