How Technology (and Scotch) is Transforming the Way Men Buy Suits

One company is incorporating modern technology to reinvent the suit buying experience.

Men have been buying bespoke tailored suits (i.e., suits that utilize new patterns for each customer as opposed to made-to-measure suits that modify base patterns)[1] for decades. Though styles have evolved, the process for purchasing a suit has remained unchanged. Men can either go to a:

- Local Tailor: Customers visit a showroom, choose fabric, and are manually measured

- Distance (online) Tailor: Customers visit a website, choose fabric, submit their own measurements

- Traveling Tailor: Tailors visit customers to show fabric and take measurements[2]

These methods use either labor intensive processes or processes that improve efficiency while potentially sacrificing fit and customer satisfaction. The local and traveling bespoke tailors typically require 3 to 5+ fittings with the customer to achieve the desired fit.[1] However, an innovative company has drastically improved their operations and transformed the shopping experience for men by combining the traditional showroom with modern technology.

Business and Operating Model

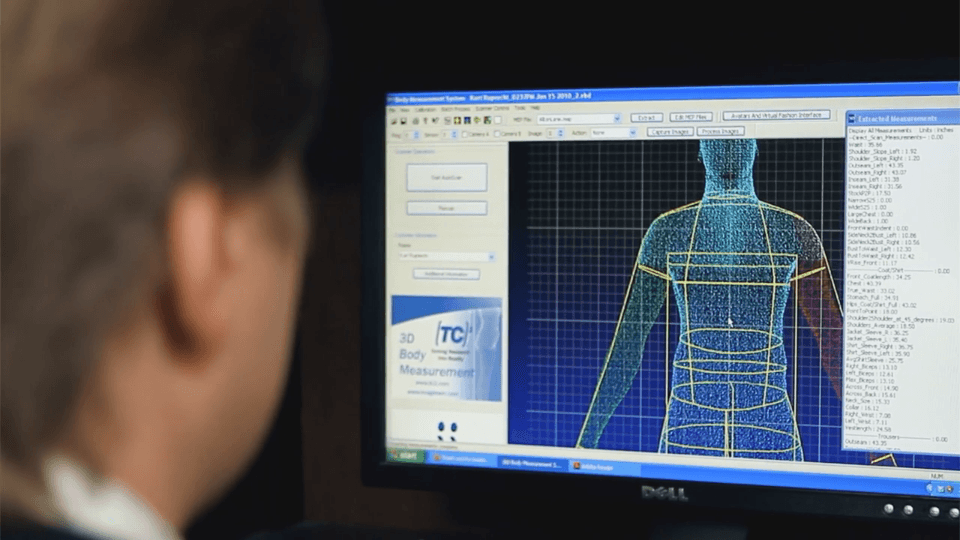

Alton Lane is a custom menswear company that offers a unique experience for customers shopping for business attire by integrating an elegant showroom with technology. When a customer arrives to a fitting appointment they first enjoy a drink while reviewing fabric options. They then are measured using 3D scanning technology (figure 1) which uses 32 sensors to capture an image of the customer within 30 seconds. This is immediately sent to the storeroom computer where employees can make alterations based on customer preferences. While the scan is very accurate, Alton Lane still takes manual measurements and fits the customers in sample garments to ensure a complete understanding of the customer’s cut preferences. After the fitting, the pattern is hand drawn and the material is laser-cut (another technology-based improvement to traditional manual cutting). The finished garment is quality checked and shipped to the customer.[3] While Alton Lane still requires manual steps within their process, they eliminate the need for multiple fittings and reduce production time through their use of technology.

Figure 1: 3D Scan Results[3]

Alton Lane also utilizes technology to improve their customers’ experience by saving their fitting information, allowing seamless purchasing of garments in the future.[3] Although the initial fitting takes time, customers who have not had any significant changes in physique are unlikely to need additional fittings.[4] Alton Lane’s confidence in their technology is evident, as they reimburse 120% up to $100 for any alterations.[5] These uses of technology will reduce the amount of time a customer needs to spend at the storeroom, improve efficiency in manufacturing, and simplify the re-ordering process.

Areas for Continued Improvement

Alton Lane stores data from the 3D scans and fittings in a database for use in future customer purchases, but is currently missing an opportunity to put this information to work. The company could utilize this data to determine trends in the preferences and body types of their customers and develop a line of off-the-rack clothing that is better fitting compared to competitors. This would be particularly appealing to men looking to purchase jackets, slacks, or shirts that are high quality and form fitting without the price tag usually associated with tailored clothing. Alternatively, they could sell their findings to high-end retailers who already participate in the off-the-rack clothing model.

Alton Lane should also invest in a cost effective, portable version of the 3D scanner that they could rent and ship to customers. This would widen their consumer base to include customers who are unable to visit the showroom or who prefer online shopping. This at-home concept has started to appear in other retail industries, such as footwear. A prime example is ‘Foot Fairy’, an app to measure children’s feet and shoe size at home, accurate to a hundredth of a centimeter.[6] Portable scanners already can be found on the market, such as the SCANIFY handheld 3D scanner system[7] or the XYZ Printing 3D scanner[8], which can process 3D images of people. If Alton Lane could partner with one of these companies, they could integrate their measurement software with the portable 3D scanners.

While there are still manual steps within Alton Lane’s processes, they are making strides to integrate a traditionally manual process with technological advancements, including 3D scanning, laser-cutting, and data storage, to offer customers a high-quality product with modern speed and convenience.

[Word Count: 695]

[1] Quora. “What is the Difference Between Made to Measure and Bespoke?” Forbes, January 16, 2013. http://www.forbes.com/sites/quora/2013/01/16/what-is-the-difference-between-made-to-measure-and-bespoke/#641272e15d85, accessed November 2016.

[2] Petrova, Veselka. “Men’s Fashion Tailoring – History and Future.” BGFN, August 1, 2014. http://made-to-measure-suits.bgfashion.net/article/9473/62/Mens-fashion-tailoring-history-and-future#popup2, accessed November 2016.

[3] Alton Lane. “How it Works.” http://www.altonlane.com/how-it-works/, accessed November 2016.

[4] Burmon, Andrew. “Best On-Demand Bespoke Suits.” Men’s Journal, August 16, 2013. http://www.mensjournal.com/expert-advice/best-on-demand-bespoke-suits-20130816/alton-lane, accessed November 2016.

[5] Alton Lane. “FAQ.” http://www.altonlane.com/faq/, accessed November 2016.

[6] Foot Fairy. “Home Page.” http://www.footfairy.com/, accessed November 2016.

[7] SCANIFY. “Meet SCANIFY.” https://scanify.fuel-3d.com/meet-scanify/, accessed November 2016.

[8] XYZ Printing. “Snap Your World in a Whole New Way.” http://us.xyzprinting.com/us_en/Product/3D-Scanner, accessed November 2016.

Main Image: Alton Lane. “Home Page.” http://www.altonlane.com, accessed November 2016.

Anthony,

How do you view the threat of increased competition as barriers to entry into the industry reduce? It seems to me that the margins are really going to get challenged going forward as brand differentiation is more difficult to sustain online. Indochino, one of the more prominent players in this space, has already slashed prices to where the average suit price is 60% of what it was 3 years ago. I foresee a future where more and more companies are providing these services online and competing on price, particularly through Pure India or Pure China plays. The net result will be lower prices for consumers, but a business whose profit margins won’t look nearly as attractive as they once did.

Jaime

This technology seems straight out of a sci-fi movie. I agree that the 3-D scanning technology can significantly improve the customer experience by shortening the time in-store. However, I’m not entirely sold on the idea that the in-person experience will disappear in the future or be reduced to at-home fittings with portable scanners. Bespoke clothing is unique for combining luxury products with high-quality and individualized service. Being served and touching / interacting with the fabrics are critical components, but neither of these translate across into the DIY at-home alternative.

While there is a lot of buzz about the death of brick-and-mortar stores, the brands and retailers seeing the most success are those who understand that online and in-person can complement one another. Brands like Bonobos, M. Gemi, Casper, and Everlane are all primarily online retailers (many got their start in e-commerce), but have since opened showrooms or physical locations so customers can interact with the products. As Ben Fischman, CEO and Co-Founder of M. Gemi, explains why they added stores. “It’s to let her try shoes on, feel the fabric and experience the brand in a tactile way that she can’t experience digitally.” [1]

[1] http://www.nytimes.com/2016/11/11/style/clicks-to-bricks-online-retailers-find-the-lure-of-a-store.html

Building on Jaime’s point, I wonder whether Alton Lane should get out of the suit selling business and just focus on developing its 3D scanning and measurement technology. There are a number of trendy companies trying to disrupt the suit industry (I have bought suits from Suit Supply and Combatant Gentleman), and perhaps Alton Lane should focus on licensing its technology to these and other companies (Jaime mentioned Indochino as well). In addition, I wonder whether it would be possible for Alton Lane to develop its technology to the point where the customer could scan himself using his iPhone at home, and then transmit his measurements and preferences to the company. This could ultimately enable Alton Lane to become the Warby Parker of suits.

Alton Lane’s 3D technology for custom fitting suits certainly sounds very disruptive in theory. However, there are many who would argue that their 3D technology is mostly hype and that it will never be able to deliver a better fitting suit than a good tailor.

In my personal experience visiting their NYC fitting location and in the experience of many others it has been the case that their suits have not fit as well as promised. [1]

Do you think this underperformance is just a temporary blip and it’s just a matter of time for them to get their 3D technology right for all customers or will this type of technology always only work for a certain subset of customers?

[1] https://m.yelp.com/biz/alton-lane-new-york

When I was reading this post, I was thinking how far Alton Lane can use digital technology to increase customer’s satisfaction. So far, I found it really valuable to have a tailored suit without additional fitting appointments (that’s very annoying!). Can this company develop new equipment to reduce the time to produce a suit? Could it be possible for the company to provide next-day delivery? or even same-day delivery?

If the garment industry can develop this kind of technology (with affordable prices), I imagine a new world full of personalized clothes with no brick-and-mortar stores, no inventory costs and same-day shipping! I’m not sure if this can come soon, but I can’t stop thinking that technology is driving us into that direction.

Thanks for the post Anthony! It’s interesting to learn about some of the innovation taking place in the men’s fashion space. The first concern I have for Alton Lane’s ability to sustain success is the quality of its suit and the strength of its brand. Although their 3D sizing technology sounds impressive and is certainly used in an innovative way at the moment, I do not think the technology is particularly differentiated and could not offer the company a long-term competitive advantage. That said, if it is ability to establish its products as truly high quality and unique, I absolutely think there is potential for them to evolve into the “Warby Parker of suits”. I was especially impressed with their existing range of stores across key first and second tier American cities (more here: http://www.altonlane.com/showrooms/). I wonder if Alton Lane believes there is an opportunity to further expand its business overseas…

Another growth opportunity that I considered was whether Alton Lane would consider growing its business to target women as well. As noted in my reply to K. Caven’s post on RtR (https://d3.harvard.edu/platform-rctom/submission/rent-the-runway-high-fashion-affordable-prices/), I have held many conversations with women regarding their style choices and decision-making process. A recurring theme is the challenge of fit. While women surely have a more diverse closet than the average man, I still find that a woman’s wardrobe contains a handful of versatile classics that could offer a promising opportunity for Alton Lane to target.