How Augmented Reality improves supply chain management for DHL

The next industry transformation in logistics may have just appeared as a pair of Augmented Reality glasses at DHL.

DHL is one of the world’s leading logistics companies, with $59 billion revenue and operations in 220 countries. The company successfully ran a set of experiments last year using smart glasses to improve its warehouse operator efficiency by 25%.1 DHL now wants to scale its new AR technology across the globe and use it to improve all parts of its supply chain operations.2

How does it work?

Augmented Reality is a technology that layers computer generated information, images and interactive features on top of a person’s real field of vision. The goal of AR is to make existing reality enhanced with more meaning and interaction. AR often takes the form of software applications run on mobile hardware, such as mobile phones or computer equipped glasses.3

In DHL’s warehousing operations, every order must be picked by an operator and moved to the right platform for customer delivery. Each operator must keep track of specified quantities, package types and zip codes, requiring great attention to detail. Operators are required to count inventory and manage data entries related to order picking. Any damage or misplacement of orders means additional cost for the company. The task of order picking accounts for 60% of DHL’s total cost of warehousing operations.

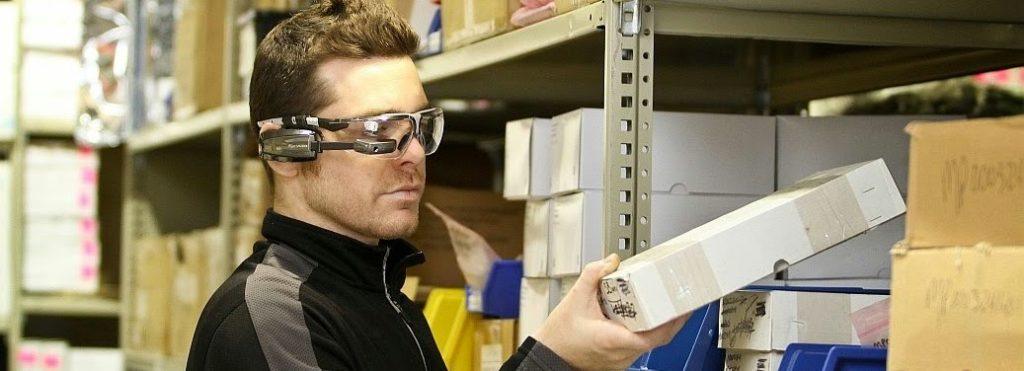

While most warehouses in the western world still use a paper based approach for order picking, DHL attempted to solve these human complexities by introducing order picking software, mounted on the operator’s head in the form of Augmented Reality glasses.

DHL’s new AR glasses improve efficiency in a number of ways. First, when workers look at digital picking lists, the glasses present the best route to load the order, reducing travel time in the warehouse. Second, workers no longer have to scan packages using barcode scanners with their hands, as the glasses do that for them. Finally, image recognition software will check that the worker has arrived to the right location when picking up the orders, and guide them to the correct item on the shelf.2

AR has had a remarkable impact on DHL, contributing a 25% increase in worker efficiency and a 40% reduction in errors in settings where it has been implemented.

What’s next?

DHL’s strategy with regards to Augmented Reality is simple: roll out the technology as quickly as possible. Following its initial success with “vision picking” in warehouse order management, DHL is now rolling out pilot programs to live warehouses in the US, UK and mainland Europe.4

DHL believes that Augmented Reality can positively impact other parts of its supply chain, as well. For example, the AR glasses can improve transportation efficiency. When picking up packages, the glasses can save time through automated completeness checks and pickup confirmations. When shipping packages abroad, the glasses can provide necessary trade documentation and translate labels. When dropping off packages, the glasses can ensure load optimization and more efficient navigation for first-time deliveries, both outdoors and indoors.

The potential for improvement outside of the warehouse also seems significant. In transportation, for example, “drivers spend between 40% and 60% of their time away from the distribution center not driving. Instead, they spend much of this time locating the correct boxes within their truck for the next delivery.”2 If DHL could use AR to eliminate half the time spent on locating packages and delivery locations, they may also see a 25% increase in worker efficiency outside of the warehouse.

What else could they do?

While DHL has found ways to improve the efficiency of its employees, many of their tasks are still repetitive and require little creativity. In order to remain competitive long-term, DHL should investigate opportunities to reduce its workforce through automation. The fully automated warehouse may remain an expensive dream, due to high R&D, fixed and maintenance costs. However, many tedious and simple tasks can all be done by machines, such as moving an order to its loading bay, registering inventory, or sorting packages by zip code.

DHL is at the forefront of using Augmented Reality in logistics, but staff wages still made up 33% of operating costs in 2015.5 By reducing this line item by 50%, the company could increase its EBIT four-fold. With Amazon and e-commerce on the rise, an innovative DHL has the opportunity to grow more quickly than the market, ultimately becoming an unquestioned leader in the express logistics space.

(747 Words)

Endnotes

1 DHL Press Release, “DHL successfully tests Augmented Reality application in warehouse”, http://www.dhl.com/en/press/releases/releases_2015/logistics/dhl_successfully_tests_augmented_reality_application_in_warehouse.html, Jan. 26, 2015, accessed Nov. 17 2016.

2 DHL, “Augmented Reality in Logistics”, http://www.dhl.com/content/dam/downloads/g0/about_us/logistics_insights/csi_augmented_reality_report_290414.pdf, Apr. 29 2014, accessed Nov. 17 2016.

3 Scientific American, “Augmented Reality: A New Way of Seeing”, http://www.nature.com/scientificamerican/journal/v286/n4/pdf/scientificamerican0402-48.pdf, Apr. 2 2002, accessed Nov. 17 2016.

4 AppsTechNews, “DHL launches next wave of ‘vision picking’ AR program”, http://www.appstechnews.com/news/2016/sep/01/dhl-launches-next-wave-vision-picking-ar-program/, Sep. 1 2016, accessed Nov. 17 2016.

5 DHL, “2015 Annual Report”, http://www.dpdhl.com/content/dam/dpdhl/Investors/Events/Reporting/2016/FY2015/DPDHL_2015_Annual_Report.pdf, accessed Nov. 17 2016.

The post clearly presents a new technology that can have a huge impact on the logistics and delivery industry.

There are other competitors apart from UPS that are looking forward to applying the technology, for example, USPS has created a detailed analysis of what are the possibilities of use of these types of wearables along the delivery process. For example, they realize that today there exists a numerous way of mapping the cities and applications that guide you through the streets, however, AR technology could be used on the last delivery task to assist letter carriers in providing consistent delivery information about the building, parking spaces, interior office routes and mailbox location. (1)

Also, as everyday security is more important, they consider that other types of security enhancements can be used via AR technology. A facial recognition program could be installed on the AR technology to verify an individual’s identity by scanning their face, providing a more secure delivery option than any option currently in the market. (1)

It would be very interesting to see how these and more wearable technology are incorporated into this type of services and how the business models of the companies are reframed to use them to a full potential.

1. https://www.uspsoig.gov/sites/default/files/document-library-files/2015/rarc-ib-15-002_0.pdf

This is really interesting. I could see a number of different uses of technology in a warehousing set up that inherently compete with each other. The one discussed above is to provide technology to the floor workers in order to improve their work efficiency. Another approach I could see is to use technology to replace the workers and automate the warehouse. While the DHL approach may cost less up front than an automated warehouse, the automated warehouse may have lower operating costs.

I have seen that FedEx seems to be investing heavily in the automated warehouse (http://www.computerworld.com/article/2549973/enterprise-architecture/extreme-automation–fedex-ground-hubs-speed-deliveries.html) and I wonder if DHL’s investments in technology may actually put them behind.

Thank you so much for the amazing article! After reading this article, I searched for AR glasses on YouTube and found pretty amazing video clips laying out the possible applications of this technology.

At first, I was concerned that VR glasses were not on the shortest cut towards warehouse automation because I thought that it required a real person to actually make usage if the technology. But after doing some additional research, it looks like warehouse robots can also be guided by a similar technology (http://www.itproportal.com/features/bring-your-vr-to-work/). I am excited how this can affect our everyday lives and hope that Samsung can take advantage if its existing VR platform to penetrate this market as well.