From Supply Chains to Supply Circles: How Philips is Rethinking Business in a World of Scarce Resources

If you could redesign the global supply chain from scratch, would it look like what we have today? Should hundreds of millions of tons of materials be ending up in landfills every year? If your answer is "no," then start thinking about the circular economy, because your competitors already are.

From Lines…

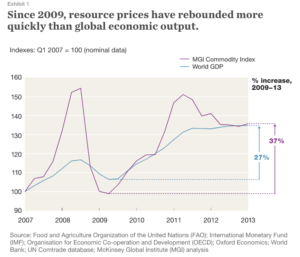

The average American generates 4.40 pounds of waste each day. As of 2013, about a third of this was recycled. That still meant Americans sent over 170 millions tons of consumed products to landfills [1]. The root cause of this is a global economy that operates with a linear mindset: extract-use-dispose. Even innocuous sounding words like “supply chain” and “consumers” indicate a linear worldview, and it’s quickly becoming unsustainable. With the global population set to grow by a third over the next 30 years and as more of the developing world rises from poverty, the global economy will increasingly demand more resources for this linear model. These demographic changes coupled with increasing resource scarcity due to climate change and resource depletion mean prices of commodities are set to rise. It’s happening already. Since the turn of the millennium, resource prices have risen faster than economic output, ending a century of price declines [2].

… To Loops

These factors require a revolution in the way products are made if destructive climate change is to be avoided and for businesses to stay competitive in the coming decades. The revolution is called the “Circular Economy,” and companies operating under this model design products for reuse, repurposing, biodegradability, and recycling [3]. The benefits are myriad. Cost savings, decreased footprints, and more robust supply chains are obvious benefits. For example, by reducing demand driven volatility in raw materials, McKinsey estimates €600 billion in savings per year in Europe alone by 2030 [4]. There are also benefits from capitalizing on changing consumer preferences and staying ahead of probable future government regulations.

Philips on the Front Lines

Philips, the Dutch healthcare and technology company, has prioritized the circular economy for the last five years. Initiatives span across the business and involve both new cost cutting and new revenue generation opportunities.

One of the most innovative initiatives involves a complete shift in their industrial lighting business. Rather than selling lights, Philips has begun to lease “lumens” to companies and cities around the world [5]. Not only does this give Philips recurring revenue and the opportunity to sell services alongside its light bulbs (8% of total revenue this past year [6]), but it also gives Philips the opportunity to repossess the lights at the end of their useful life to ensure the components can be reused in new manufacturing. In the healthcare space, Philips has added new manufacturing capacity near to its customers for repurposing and rehabilitating outdated equipment [7]. Different customers have different needs, and Philips has capitalized on the opportunity to turn one company’s trash into another company’s treasure.

Alongside initiatives to repurpose equipment and reuse components have come cost savings that insulate Philips from cost pressure and risky, diffuse supply chains. With relatively small upfront investments in design, Philips has reduced the number and types of disposable inputs in its products and significantly improved its product’s total lifetime costs. Philips has accomplished this by reimagining the relationships with its suppliers and spreading realized savings throughout the value chain [8]. Not only does this create stronger supplier bonds, but it also begins to create an ecosystem for the circular economy, which will make future savings opportunities even easier to realize.

Philips Can Continue to Close the Loop

Philips has cemented itself as a leader in the circular economy. The change has come from the top-down, and Philips’ CEO, Frans van Houten, has been a leading advocate for the circular economy in publications and forums around the world [9]. However, not every developed economy is supporting the circular shift like the Dutch. Philips’ competitors, like GE, also support sustainability in their own ways, but the circular shift has been slower to materialize in the US. If it’s going to be successful in the long run, an entire ecosystem must develop in order to close the loop and provide the kind of cost savings and environmental benefits that are needed. Granting interviews and supporting research as van Houten has done are steps in the right direction, but Philips may want to consider furthering the ecosystem with such activities as providing consulting services. The more companies follow in Philips’ footsteps, the more Philips can help its core industrials business in the long run. The circular economy has network effects; one company can’t realize its full potential alone.

As one of the first movers in a networked ecosystem, what strategies can Philips employ to accelerate its savings without losing competitive advantage? What responsibilities do businesses have when system-wide economic improvements have dispersed benefits that are much larger than improvements to their own bottom lines?

(763 Words)

References:

[1] Environmental Protection Agency. “Municipal Solid Waste”. 2016. https://archive.epa.gov/epawaste/nonhaz/municipal/web/html/

[2] Nguyen, Hanh, et al. 2014. “Remaking the Industrial Economy”. McKinsey & Company. https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/remaking-the-industrial-economy

[3] “Towards the Circular Economy”. 2013. Ellen MacArthur Foundation. https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf

[4] “Europe’s Circular-Economy Opportunity”. 2015. McKinsey & Company. https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/europes-circular-economy-opportunity

[5] Fleming, Thomas, et al. 2014. “Toward a circular economy: Philips CEO Frans van Houten”. McKinsey & Company. https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/toward-a-circular-economy-philips-ceo-frans-van-houten#0

[6] Anzilotti, Eillie. 2017. “If These Giant Companies Can Switch to the Circular Economy, So Can Anyone”. Fast Company. https://www.fastcompany.com/40425022/if-these-giant-companies-can-switch-to-the-circular-economy-so-can-anyone

[7] “Philips takes circular economy to healthcare and inaugurates a new imaging systems refurbishment facility in Best, the Netherlands”. 2014. Philips. https://www.philips.com/a-w/about/news/archive/standard/news/press/2014/20141113-Philips-takes-circular-economy-to-healthcare-and-inaugurates-a-new-imaging-systems-refurbishment-facility-in-Best.html

[8] “We are embracing circular procurement as a key driver of the circular economy”. Philips. https://www.philips.com/a-w/about/company/suppliers/supplier-sustainability/our-programs/circular-procurement.html

[9] “Public-Private Cooperation Will Speed Progress towards Sustainable Development Goals”. 2017. World Economic Forum. https://www.weforum.org/press/2017/09/public-private-cooperation-will-speed-progress-towards-sustainable-development-goals/

While I agree with Philips’ goal of reducing waste and creating a more sustainable economy, I’m skeptical on the true environmental benefits. Because they now need to repurpose old equipment, they are incurring additional environmental costs associated with the transportation. Further, you mentioned Philips needed to build new manufacturing facilities near their customers to repurpose the old equipment. The net effect on the environment of creating the building materials, constructing the building, and operating the facility would take so long to recoup in terms of environmental benefits that I am skeptical that this circular supply chain would outperforms other forms of environmental protection. Given the upfront environmental costs of implementing a circular supply chain for a single company, it would seem counterproductive if multiple companies set up similar facilities in the same geographic areas. As additional companies adopt this sort of supply chain, significant regulatory progress would need to be made to prevent duplication of effort, allowing some of the benefits to be unlocked.

Great article, AR – thanks for sharing. While I fundamentally agree with the idea of “circular economy”, I am skeptical of its successful adoption in the current business environment. Unlike Philips, which to your point has done a very good job of implementing this, other companies may not be able to move in the same direction simply because of the misalignment of such potential initiatives with the notion of shareholder value maximization. In the current business environment, adoption of “circular economy” will likely vary and be limited, depending on the industry –

for instance, most consumer packaged goods businesses will find it extremely difficult to become fully sustainable. As long as there is a demand on the consumer side, there will be companies supplying goods motivated by maximiznig shareholder value (i.e. profits). True change, in my opinion, heavily relies on the shift of consumer behavior towards sustainability.