Cognex – riding the wave of digitization through machine vision

CGNX trades on the Nasdaq and manufactures machine vision tools that substantially increase the speed at which products can be manufactured and the quality of the end-product.

Cognex (NasdaqGS: CGNX; Market Cap: $5 billion) is a manufacturer of machine vision devices. These devices guide robots to perform tasks on manufacturing / quality control lines that were previously performed by humans such as checking the fill level of a Poland Spring water bottle to make sure a customer doesn’t get short changed on the amount they ultimately buy.

How does the company use digital technology to develop its business model?

In my mind, Cognex has differentiated itself and managed to provide sustaining customer value by creating the best digital technology in the market and also by arriving first. Cognex was founded in 1981 by Bill Silver, an MIT engineer, and placed into the market a digital technology that previously did not exist. Not only do the cameras perform tasks more efficiently than humans but they also took manufacturing processes to new levels. Many manufacturing processes today have passed the limits of human eyesight. Manufactured items are often manufactured too quickly or with tolerances too small to be analyzed by the human eye. In these instances, Cognex cameras bring tremendous value to the customer by being able to analyze products in real time and digitally transmit information to robots to ensure products are made efficiently and with unparalleled quality. The company is continually focused on ensuring that its technology is the best in the market, pouring 15% of revenue into R&D and having 660+ issued or pending patents worldwide.

This business model also creates substantial value by having an impact on a variety of different industries. For instance, machine vision can determine the position of a printed circuit board so that a robot can automatically be guided to place electronic components on that board in the right place (something we learned from our TOM simulation is quite difficult to do manually!). The business has technology that can rapidly read barcodes on different parts (for instance an airbag) so that it can be tracked throughout a manufacturing line. In Pharma, machine vision can check for even the slightest foreign debris to ensure nothing dangerous or unexpected is in a medicine prior to shipping. Lastly, when there is an extremely detailed gauging that must take place (e.g. evaluating the size of an industrial bearing prior to final assembly), machine vision can accurately and rapidly fulfill the task. The various applications of this product create a highly differentiated business model because it is exposed to a plethora of end-markets which all realize substantial value when supplanting human labor with machine vision.

How does the Cognex operating model ensure that the Company is consistently creating value for the customer?

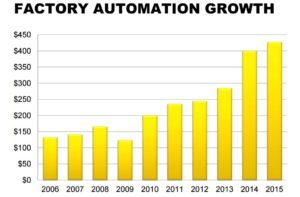

The market that Cognex plays in is a highly growing market.

As a result, the Company has benefited substantially from these tailwinds growing from $274 million of revenue in calendar year 2011 to $451 million of revenue in the calendar year ended December 31, 2015. However, despite this growth, Cognex has not sacrificed on service / quality to the customer. Its employee base consists of highly educated engineers who are constantly innovating the cameras, allowing its technology to continue to outperform competitors. 37% of Cognex employees are engineers. Furthermore, 36% of employees have advanced degrees.

Cognex also delivers on its promise to offer an unparalleled machine vision experience by guaranteeing substantial after market support services. Services include maintenance and training services to customers who have purchased the cameras. Maintenance and support programs include hardware support programs that entitle customers to have failed products repaired, as well as software support programs that allow customers to access the latest software updates. The Company employs a large number of field engineers who are in close proximity to the Company’s customers and can help them navigate the complex machine vision technology they have purchased.

Steps going forward

Going forward the business should continue to invest substantially in R&D to remain a technological leader. I think the most important consideration for any company that digitally transmits so much data (as these cameras do) is to ensure that data is sent safely. We have seen numerous businesses lately (target credit card breach, etc.) in which data was not securely treated and the business operation as a result had to take a step back. I would like to see Cognex more heavily invest in the security of its cameras to ensure that the precious data these cameras interface with is safe in its manufacturing partners’ eyes. Nonetheless, I believe this company has already substantially improved productivity and quality in manufacturing. [749 Words]

[1] Cognex 10K for the Fiscal Year Ended December 31, 2015

[2] Cognex Investor Presentation for the Quarter Ended September 30, 2016

[3] www.cognex.com

[4] http://www.visiononline.org/Computer-Vision-vs-Machine-Vision/content_id/4585

[5] http://www.wsj.com/articles/machine-learning-radiology-startup-zebra-medical-vision-raises-12m-1464105600?mg=id-wsj

Great post Evan. Machine vision is such a cool field especially since we are still barely scratching the surface of what is possible. Your point about data control is extremely valid and many companies spend a crazy amount of money and time on that problem. However, I feel in Cognex’s case, the type of data they are dealing with does not really need to be treated with the same level of care as credit card info. From looking at their website, it seems like they are mainly focused on closed loop QA through machine vision. (i.e. goods coming off a line need to be checked visually against some KPI or a barcode needs to be read at high accuracy and speed) In all these cases, and the examples in your post, most data need not even be stored for very long periods of time.

The next wave of machine vision problems though, the kind that Bastianne brought up in class for example, where her company had technology to determine people’s demographics through machine vision, would require a heightened level of data control. While machine vision is just the start today, other sensors like fingerprint scanners, iris detectors and sweat sensors have the ability to record much more Personally Identifiable Information (PII) from a person making it ever more important for companies to have a solid Data privacy strategy and controls.

Great post Evan! I think another interesting future direction Cognex could look into is using it’s vision technology for other applications. One example would be looking into vision for autonomous vehicles – Cognex cameras are incredibly good at reading precise details and it is not hard to imagine that this capability could be important in more scenarios than manufacturing lines as we look to a future where robots are all around us.