Boeing: Making Metal 3D Printing take-off

Boeing is in the “rocket science” business, hence as the common idiom goes, it is no secret its manufacturing process is quite complex…

With millions of parts that go into the making of each plane and space launch systems – Boeing is peering into new technologies to look for faster, cheaper and safer ways to produce its planes. Metal Additive Manufacturing (i.e. 3D Printing) is at the forefront.

Boeing is in the “rocket science” business, hence as the common idiom goes, it is no secret its manufacturing process is quite complex…

With millions of parts that go into the making of each plane and space launch systems – Boeing is peering into new technologies to look for faster, cheaper and safer ways to produce its planes. 3d printing, also known as Additive Manufacturing (AM) is at the forefront.

1. Importance: Why is 3d printing on Boeing’s radar?

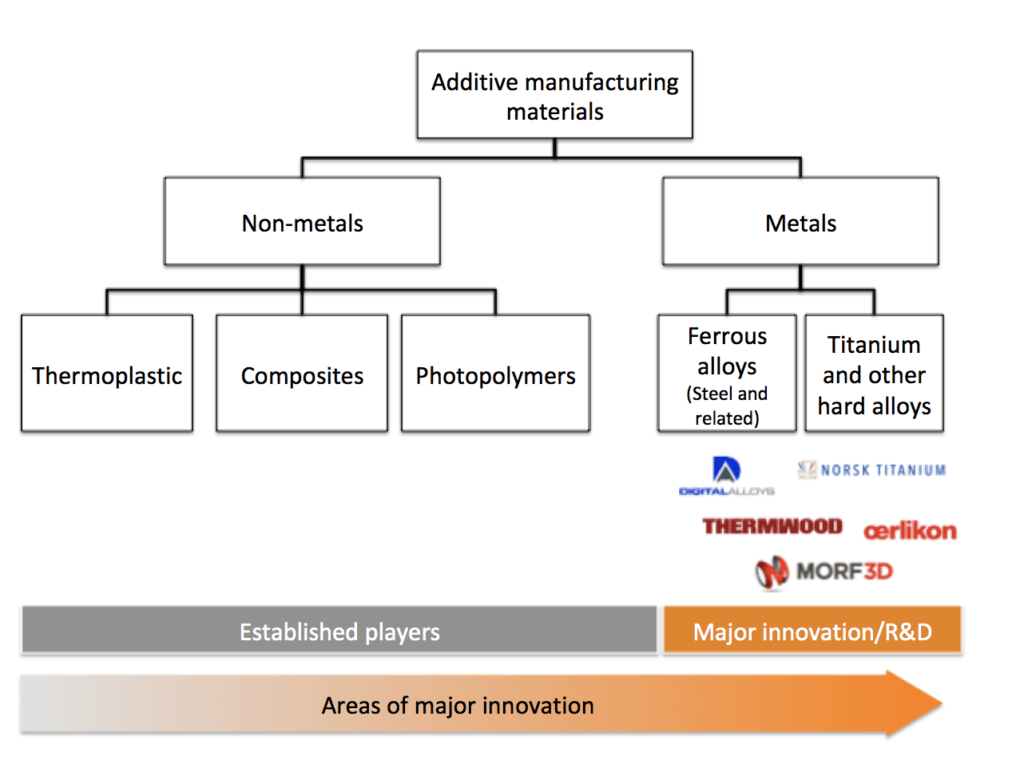

Boeing’s business has presented itself as an ideal opportunity for the application of 3d printing which explains the companies investment in several 3d printing startups such as Digital Alloys (multi-metal 3d printing), and Morf3D (titanium and aluminum 3d printing). So far, AM techniques have concentrated on the production of plastic and polymers, but Boeing is interested in applying the process for metallic parts as well.

“Developing standard additive manufacturing processes for aerospace components benefits both companies and empowers us to fully unleash the value of this transformative technology,” says Kim Smith, VP and GM of Fabrication for Boeing Commercial Airplanes and Boeing Additive Manufacturing. [1]

Aerospace parts are characterized by high mass criticality, multifunctional structures, high-end finish, low production volumes, high reliability and speed to market. Additionally, the complex function of these parts leads to complex geometries and structures that are difficult to manufacture using traditional methods. Complexity and manufacturing costs fly together and this is why the largest plane manufacturer wants to bring complexity down. [3]

Old manufacturing techniques have many disadvantages. For example subtractive techniques (where a block of material is carved to create the part) waste excess materials and require expensive assembly. Additive manufacturing allows for the creation of components in single pieces thus reducing the quantity of material needed, the number of parts [3] and ultimately, the cost of manufacturing [4]

2. Short and Medium term: What’s in the horizon for Boeing?

Given the potential upside associated with this new technology, Boeing is partnering and investing heavily in new AM techniques.

To look at where the company is headed, it is useful to look at Boeing’s recent activity in that space.

On the one hand, it has invested directly in companies such as Digital Alloys [5] (August 2018) and Morf3d (April 2018) [6]. Digital Alloys is a young startup that has developed a technique to create parts from different metallic material. Brian Schettler, managing director of Boeing HorizonX Ventures expresses his company’s objective from the acquisition: “Our investment […] will help Boeing produce metal structural aerospace parts faster and at higher volume than ever before”. [5]

On the other hand, Boeing has partnered with players such as Thermwood [7], Oerlikon [8] and Norsk Titanium[8]. Its collaboration with Norsk Titanium has yielded the first additively manufactured titanium parts on a commercial airplane. With Oerlikon, a Swiss-based supplier, Boeing created a research agreement to develop processes for titanium powder additive manufacturing.

Taking a step back it is quite clear that the company is looking to adapt AM to metallic alloys – an area where AM has yet to be proven and scaled for manufacturing purposes.

To accelerate its R&D, it is important for Boeing to nose-dive in the direction of a faster development. So far it has relied on a network of outside partners that covered overlapping areas of research and development. To shorten its journey to success, Boeing should attempt to consolidate its base of companies to benefit from the cross leanings between companies.

Such initiatives can take multiple shapes such as driving mergers of companies in that space or creating “Centers of Excellence” to share learning amongst the various partners. This would allow Boeing to ramp up faster to applying AM to its design process.

Additionally, bringing the researcher efforts more closely to its design team could allow a faster iteration process that would lead to a faster development. (768 words)

4. Question: How to see beyond the fog?

Metal AM is still being tackled to be fully adapted to airplane manufacturing, areas of development include: improve surface finish, part strength and reduction of layer thickness [3].

Currently AM applications in aerospace are limited to secondary non-critical parts and it will take time to further the certifications required to use AM for the critical metallic parts of airplanes.

Finally, the last question that looms in the horizon is the ability of companies to adapt its design process to AM which requires a different set of skills than the ones currently used in airplane design.

[1] http://additivemanufacturing.com/2018/04/23/boeing-horizonx-invests-in-3d-printing-startup-morf3d/

[2] C. W. J. Lim, K. Q. Le, Q. Lu and C. H. Wong, “An Overview of 3-D Printing in Manufacturing, Aerospace, and Automotive Industries,” in IEEE Potentials, vol. 35, no. 4, pp. 18-22, July-Aug. 2016.

[3] G. J. Schiller, “Additive manufacturing for Aerospace,” 2015 IEEE Aerospace Conference, Big Sky, MT, 2015, pp. 1-8.

[4] A. Angrish, “A critical analysis of additive manufacturing technologies for aerospace applications,” 2014 IEEE Aerospace Conference, Big Sky, MT, 2014, pp. 1-6.

[5] “Boeing HorizonX Ventures Invests in High-Speed Metal 3D Printing Company Digital Alloys”, August 7, 2018, CHICAGO, Aug. 7, 2018 /PRNewswire, URL: https://additivemanufacturing.com/2018/08/07/boeing-horizonx-ventures-invests-in-high-speed-metal-3d-printing-company-digital-alloys/

[6] “Boeing HorizonX Invests in 3D Printing Startup Morf3D”, CHICAGO, April 23, 2018 /PRNewswire/ , URL: http://additivemanufacturing.com/2018/04/23/boeing-horizonx-invests-in-3d-printing-startup-morf3d/

[7] “Boeing and Thermwood Partnership to Demonstrate New 3D Printing Technology”, October 2018, URL: http://additivemanufacturing.com/2018/10/10/boeing-and-thermwood-partnership-to-demonstrate-new-3d-printing-technology/

[8] “Oerlikon and Boeing to Create Standard Processes for 3D-Printed Structural Titanium Aerospace Parts”, February 20, 2018, URL: http://additivemanufacturing.com/2018/02/20/oerlikon-and-boeing-to-create-standard-processes-for-3d-printed-structural-titanium-aerospace-parts/

[9] “Norsk Titanium to Deliver the World’s First FAA-Approved, 3D-Printed, Structural Titanium Components to Boeing”, April 10, 2017, URL: http://additivemanufacturing.com/2017/04/10/norsk-titanium-to-deliver-the-worlds-first-faa-approved-3d-printed-structural-titanium-components-to-boeing/

3D printing has come a long way. Pretty soon, instead of 3D printing the metals/parts, they’ll be able to print the entire plane. That’ll be the day!

I understand the usefulness of the technology in the space. I would like to learn more about how much more or less time 3D printing takes than your traditional way of procuring the required materials. Is producing the metal in-house really that much better than outsourcing it?

Additionally, how reliable are these metals? Having a plane malfunction because of a poorly-made piece of metal would be detrimental to the advancement of this technology. Know AM is currently only used for non-critical portions of the plane. In the event AM is “proven”, that is demonstrated via no incidents of metal malfunctioning, how receptive will passengers be to riding on planes with 3D parts. I guess as a passenger we don’t really think about plane parts but I’d be skeptical if I ended up finding out my plane was made of printed materials.

Given the huge potential that 3D printing represents for Boeing, I wonder if it would make sense for the company to invest in developing its own 3D printing capabilities. While passively investing in startups is a way to stay on top of R&D in this market, I worry about competitors like GE who have made more aggressive bets (In 2016, GE acquired two metal 3D printing companies for $1.4 billion)

No doubt, 3D printing is the technology that can change the total structure of manufacturing business. However, I’m still skeptical about using 3D printing technologies to Aerospace. Usually 3D printing is mostly effective when the prototyping process is fast and there are a lot of needs on customization, but Airplane is relatively slow industry to develop a new product and also most of products are quite standardized. Moreover, the size of parts is very big and the safety of products (airplanes) is important. Therefore, I think Boeing should take more time to test the technology within its organization, rather than utilizing companies it cannot fully control.

This is super promising technology in the aerospace industry. I think an interesting use case would be eliminating interior, non-functional material in parts. That would reduce the weight, thus reducing fuel cost per flight.

3D Printed components have high variable costs, but low fixed costs. Do you think airplanes are made in small enough batches that the low fixed cost option makes more sense than a low variable cost (more traditional) option?

As Hanyin mentioned, this seems like an area that they need to invest heavily in — buy or invest in companies, get an internal group working on AM… they must do something to avoid the threat of disruption.

One thing I would like to add to the article and the comments above is that AM could drive huge potential weight savings on parts. This could happen by eliminating the fasteners, screws, bolts, or other means of putting traditionally manufactured pieces together. While I agree with July that the industry is slow to develop and requires intense quality control, the potential benefits of shaving a few ounces here and a few ounces there are enormous.

I love the idea of 3D printing for planes however I am a bit concerned how safe this will be. I would guess that planes would probably be one of the last items to be 3D printed. But definitely, having the ability to use 3D printing for planes, it could significantly reduce plane costs and therefore help revolutionize the industry once again.

A very interesting read and thank you so much for your time!

This is a very interesting use case for AM, even though the technology itself is still under development but Boeing clearly has enough resource to experiment and pushes forward, however, the technology can also be dangerous especially in the airlines’ industry.

This was a super informative article on a topic that I had barely understood until reading your article. Similar to a few others who have commented, my concern is also about safety. Do you think Boeing can try the durability and safety of 3D printed materials on non commercial aircraft in the earliest phases of use? For example, drones and other types of un-manned aerial vehicles?

This is an interesting article exploring 3D printing application in Boeing. I particularly enjoyed how to author brought up its in limitation in critical vs non critical parts of the airplane. Would also be interested to hear how Boeing try to address the quality assurance issue of 3D in this very sensitive space. Especially, for barriers to entry for military aircrafts, what are the effective ways to mitigate the risk and concerns.