BHP Billiton: Productivity enhanced by machine learning in the mining industry

Mining is one of the first industries to start seeing a return on their early investments in machine learning. But why is artificial intelligence so important for this industry?

The importance of machine learning in the mining industry

During the early 21st century, many commodities prices including minerals significantly rose due to the large growth of emerging markets. During this phase, all mining companies were solely focused on increasing their production, without worrying much about their productivity and costs. That’s why when prices started falling in 2014, many companies were not prepared and had to make strong moves to increase their productivity. [1] I was able to experience this cost-cutting sense of urgency while working for multiple mines in South America.

After downsizing the overhead and negotiating contracts with suppliers, the only way to reduce yours costs is to work on the productivity of your processes. The mining industry produces a significant amount of data at multiple levels of their processes, however much of it is very complex and difficult to analyze on real time. Using machine learning algorithms, makes it possible to take decisions with the data without delaying the processes. [2]

Finally, given the scale of mining operations and the high cost mining equipment, even increasing productivity or utilization on a small degree can have a high impact on financial performance of the company.

Machine learning innovation on BHP Billiton

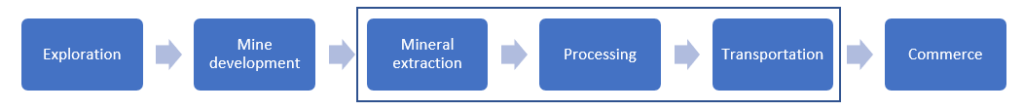

The mining macro processes are shown on graph 1. Most of the machine learning applications that BHP Billiton is working on for the short and medium term are concentrated in the extraction, processing and transportation of the minerals, mainly because they involve a higher number of repetitive activities. [3]

Figure 1

In mineral extraction, BHP is working on two fronts: self-driving trucks and automated drills. The company is implementing fifteen automated trucks in an iron ore mine in Australia. Automating trucks inside a mine has benefits in terms of preventing accidents caused by sleepy drivers, decreasing variability among performance of different vehicles and improving vehicle utilization, therefore maximizing output. The use of autonomous drills to replace the traditional manual drills has helped BHP improve its productivity by 16%. Drills are used in mining to dig holes to insert explosives for the blasting, which allows shovels and trucks to remove all the material. Also, the drills can test how hard or soft the ground is, so that later they can precisely estimate the quantity of explosives required. [4]

Figure 2

In the minerals processing stage, BHP is introducing a system to automate the decision-making process of choosing what crushers better fits the batch of materials is being transported in a truck. This allows them to reduce costs and idle time, therefore improving its crushers utilization and output. [3]

Finally, BHP is also working to automate its logistics and transportation of the minerals. Typically, ores are transported from by train to a port, and then loaded into vessels. Transportation in many operations can easily become the bottleneck, and for that reason, optimizing utilization and capacity is a priority, which is achieved by having autonomous trains and an autonomous loading process to move ores from the train into a vessel. [5]

Is the company doing enough?

Even though BHP is innovating and finding ways to apply machine learning along all the value chain, there are still multiple areas where it could dive deeper. The two areas where I believe there could be more impact is on mineral processing and maintenance.

After the ores are extracted from the mines, they must go through different physical and chemical processes to concentrate the metals they are looking to harvest. These processes are usually operated under parameters based on historical data and estimations, but given the number of sensors and real-time data, BHP could start using machine learning algorithms to optimize on real time the parameters of their processing plants and obtain higher recovery rates.

The maintenance department could also take significant advantage of applying machine learning algorithms. Reactive and preventive maintenance are an important source of waste for equipment utilization. While reactive maintenance can abruptly stop your extraction or processing lines, preventive maintenance when it’s not required can also decrease your equipment utilization and output rate. By levering the sensors of the vehicles and other equipment, and applying machine learning algorithms, BHP could apply predictive maintenance, which would make them park their machines only when it is absolutely required.

Will technology be enough to sustain profitability in this declining margins industry? Will there be social consequences of cutting down labor due to machine learning in an industry that already employs few people and that many times has a negative perception among the local communities? These are some of the questions that time will solve.

(761 words)

Sources

[Figure 2] Komatsu Ltd, “Autonomous mining dump truck Komatsu IAHV”, gruzovikpress.ru, Feb 2018, http://www.gruzovikpress.ru/article/15015-avtonomniy-karerniy-samosval-komatsu-iahv-tochnoe-predskazanie-kontseptsii/

[1] EY, “Productivity in mining: now comes the hard part”, ey.com, 2018

https://www.ey.com/Publication/vwLUAssets/EY-productivity-in-mining-now-comes-the-hard-part/$FILE/EY-productivity-in-mining-now-comes-the-hard-part.pdf

[2] Hyder Z., Siau K., Fui-Hoon Nah F., “Use of Artificial Intelligence, Machine Learning, and Autonomous Technologies in the Mining Industry”, Association for Information Systems, May 2018, https://aisel.aisnet.org/mwais2018/43/

[3] Jurgens D. (BHP Billiton CTO), “Creating the future of mining – integration and automation”, bhp.com, 01 Nov 2017, https://www.bhp.com/media-and-insights/reports-and-presentations/2017/10/creating-the-future-of-mining-integration-and-automation

[4] Australian Mining, “How Epiroc is making autonomous mining a reality”, australianmining.com.au, 04 July 2018, https://www.australianmining.com.au/features/epiroc-making-autonomous-mining-reality/

[5] Crozier R., “BHP Billiton goes cloud for robot rail facility”, itnews.com.au, 06 April 2015, https://www.itnews.com.au/news/bhp-billiton-goes-cloud-for-robot-rail-facility-402783

What drew me to this article was my own fascination with how the mining industry is using machine learning. You hear about large tech companies leveraging data and become efficient with machine learning – but you rarely hear about industries like mining which have the perception of being stuck in the past. While the above article raises some interesting aspects of how BHP uses automation, I wonder though if their actions are truly machine learning?

Within self-driving trucks and automated drilling are they using data to make better informed decisions? Are the drills learning how better to drill over time? I do see some opportunities for a company like BHP to use machine learning in the future. Though I am not an expert in this field, I see an opportunity to use algorithms to make decisions on where / how much to drill – then having these algorithms learn from the return to make better informed decisions. Could use technology like this be the future of mining?

Thanks for the interesting read! I really appreciate the research you put into this. I find it really interesting how self-driving trucks are already being piloted while self-driving cars are still struggling to gain regulatory approval. I think this probably has a lot to do with how self-driving trucks operate in a much more controlled environment. I wonder whether some of the lessons that engineers learn from deploying self-driving trucks to roads will help speed up the research and development of market-ready self-driving cars.