AUGMENTED REALITY: A GAME-CHANGER FOR THE LOGISTICS OF TOMORROW

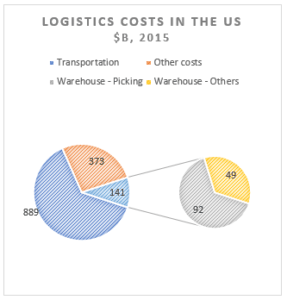

Warehousing operations is big business. It is a $141B business in the US alone and accounts for 10% of all logistics costs [1].

Estimates suggest picking items from shelves represents 65% of those costs, or $92B (Figure 1) [2]. The process is still heavily manual. Pickers carry a hand-held scanner with them, searching for the right item, scan it and place it in a cart. It is slow and error prone. Errors must be prevented as they typically result in high follow-up costs including re-stocking and administrative costs.

Augmented Reality: an Opportunity to Increase Productivity in Warehouse Operations

AR is a not-so-new, yet underutilized technology that allows the superimposition of information in the user’s line of sight [2]. It can help warehouse operations in three major ways: optimized picking, warehouse planning and quicker training of resources [3].

Optimized picking

Augmented Reality and head-mounted displays free up the pickers’ hands, allow the display of the picking list in the picker’s eye-sight, automatically scan barcodes, optimize indoor routing and help locate items on the warehouse shelves. Through a reduction in error-rate and search time, optimized picking is the most obvious advantage of AR in warehouses [2].

Warehouse planning

As warehouses become more complex and house new value-added services, AR can help experiment, in “real-life”, proposed changes to the warehouse layout and processes. It converts 2D plans to a 3D and life-sized environment, which speeds up the process of planning and reduces the occurrence of “run-time errors” [2].

Quicker training

The distribution industry is one of the largest occupational segment of the temporary staffing market [4]. Between 11% and 18% of workers are temporary [4]. They each need to learn the layout of the plant and must go down the learning curve before being fully operational. AR can accelerate the ramp-up period of these workers by walking them through their first shift step-by-step, with much lesser need for training.

Intel’s results with AR suggests an opportunity of at least ~$25B for the logistics sector

“In its distribution center in Arizona, Intel successfully deployed the Pick-by-Vision solution xPick, developed by Ubimax.” Ubimax is a market leader for industrial wearable computing solutions.

According to the latest results, Intel improved its KPI of “pick-time-per-box” by 29%, with minimal ramp-up time. [5]

“On the very first use without any training, order pickers were already 15 percent faster using Vision Picking compared to the picking process with hand-held scanners.” [5]

These early results not only encouraged Intel in its endeavor to stay relevant through implementing AR in its daily activities, but also suggest a tremendous opportunity for cost takeout in the US logistics sector. A reduction of 29% in warehousing operation costs could amount to ~$25B [1]. Error-rate is also down to almost 0%. [5]

This promises to attract players to implement this technology. DHL, a global supply chain company already started rolling-out AR in its warehouses and noticed a similar 25% increase in productivity [2], further confirming the optimization potential.

Intel’s management seems to be aware of the threat of non-sustainability of this cost advantage, and is moving quickly to implement AR in its warehouses across the globe [5].

Warehouse Operations: Only the Tip of the Iceberg

Although a tremendous opportunity for AR in supply chain lies within warehouse operations, managers must consider the transportation cost bucket ($889B). As a starting point, two applications should be explored: transportation optimization and last-mile delivery. [1]

Transportation optimization

AR can achieve more effective pick-ups through reduction in transportation time, detection of potentially damaged items and facilitated completeness checks. AR devices could detect the number of pallets or parcels that have been picked-up, assess their status and confirm that the order is complete. [1] It can also assist truck drivers in heavy traffic through heads-up displays and optimize the cargo loading process through the projection of loading instructions on a head-mounted display.

Last-mile delivery

“Estimates suggest that drivers spend between 40 % and 60% of their time away from the distribution center not driving.” They are instead searching for boxes or where to deliver them. [1] AR could assist drivers in their day-to-day job by decreasing the reliance on memory from the loading process, displaying exactly where in the truck is the next package to be delivered. The so-called “last-meter” delivery could also be improved through enhanced close-quarter navigation and crowd-sourcing of delivery data (i.e., Where exactly is Soldiers Field Park Building 3?).

What does the future hold: enhanced humans or humanized computers?

As Intel and other firms keep “enhancing” its human employees with technology, and other hardware firms keep “humanizing” their computers through machine learning and AI, one could question what the real future of logistics is.

- Human pickers with “enhanced” vision or robots with judgment capabilities?

- Human truck drivers with robot-like capabilities or driver-less trucks?

(796 words)

Sources:

[1] Schulz, John, “2016 State of Logistics Report: Pursue mutual benefit”, Logistics Management, 55, 7, pp. 22-25, Business Source Complete, EBSCOhost, viewed 3 November 2017.

[2] Porter, Michael and James Heppelman. “Why every organization needs an augmented reality strategy” Harvard Business Review (November-December 2017): 46-57.

[3] Kückelhaus, Markus (Dr.) “Eleven reasons to consider augmented reality in logistics”, Operations Management (1755-1501), 41, 2, pp. 16-18, Business Source Complete, EBSCOhost, viewed 3 November 2017

[4] “Trends in the warehousing and distribution industry” Staffing Industry Analysis (December 13, 2016), https://www2.staffingindustry.com/Editorial/Industrial-Staffing-Report/Dec.-15-2016/Trends-in-the-warehousing-and-distribution-industry, accessed 4 November 2017

[5] “Intel Achieves 29% Efficiency Increase with Ubimax Solution xPick,” press release, April 6, 2017, on Intel website, https://www.reconinstruments.com/2017/04/intel-jet-pro-efficiency-increase-ubimax-xpick/, accessed 4 November 2017.

Featured image: Intel, “Intel ADC Pilot – Recon Jet Pro,” YouTube, published March 16, 2017, https://www.youtube.com/watch?v=zgqySidLHzI&t=2s, accessed 15 November 2017.

Figure 1: Schulz, John, “2016 State of Logistics Report: Pursue mutual benefit”, Logistics Management, 55, 7, pp. 22-25, Business Source Complete, EBSCOhost, viewed 3 November 2017.

Image 1: “DHL Successfully Tests Augmented Reality Application in Warehouse” Supply and Demand Chain Executive, http://www.sdcexec.com/news/12040626/the-wearables-and-augmented-reality-software-can-improve-the-picking-process-by-25-percent, accessed 3 November 2017

AR can significantly improve human operations, but in the end, the operation will still be held to human limitations. We can probably agree that delivery and picking are not very value-added tasks in which a human being can bring enormous value: they are usually a routine, require tiring activities (such as long driving or parcel lifting) and they are prone to errors. True, AR can enhance the current situation but, would it not make more sense for a firm to invest in a technology that can entirely remove the human factor and improve productivity by an order of magnitude?

The technology is already being deployed on the warehouse part of the business, with a firm as Symbotic [1] already selling fully automated warehouses to its clients. On the driving side, self-driving trucks still seem a bit far from being a reality but tremendous improvements in the last years [2], thus AR would probably be only a temporary solution.

[1] http://www.symbotic.com/

[2] “Self-driving car technology: When will the robots hit the road?”, Mckinsey, May 2017: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/self-driving-car-technology-when-will-the-robots-hit-the-road

Thanks for sharing Jasmyn. With the rise of e-commerce and the power of amazon, warehousing will be an increasingly important aspect of the world’s supply chain. At the TOM field trip we went to a company call Symbotic which installs and runs fully automated warehousing systems in client companies’ existing infrastructure space. The technology they use to break down inventory, categorize, store, collect, and ultimately repackage is tremendous. I can’t get into details because of an NDA but would be happy to chat further if your interested.-BK

NDA’s don’t apply to Section I. We can tell each other everything. Next time they make you sign one, let me know and I’ll send our legal rep with you.

This is a really interesting article.

I absolutely agree that AR is underutilized, although I think rightly so since AR is not yet a mature technology. One promising utilization of AR is actually in remote surgery. If a patient can be sufficiently and accurately scanned, then a surgeon can operate remotely as if he/she is operating on the actual patient!

Back to the warehouse business, I wonder if companies should transition to full automation and involve no people or should they invest in letting people using AR. I suspect the former since human are simply not as good as a pure labor force as robots. I really like the last mile delivery using AR since drivers, doing both driving and offloading can hardly be replaced by robots.

I think it seems inevitable that humans will become less and less important in logistics, and that warehouse robots and driverless trucks will eventually replace the vast majority of humans roles. That, however, does not mean AR and the suggestions you make will not provide impressive efficiencies before the robots take over! It is all about timing. The AR technology you describe is already available and in the next few years will likely be widely used. In warehousing, I think robots will come very soon after it is widespread and so the AR benefits will be shortlived; we can already see that Amazon are already working hard to robotise their picking processes. But I think we could be a further 5-10 years before we have the legislation and technology to truly consider driverless truck deliveries (ignoring delivery-by-drone for the moment). This suggests the AR technology you mention for delivery will likely remain relevant for longer than that for warehouse operations, before being replaced by other advanced technologies.

Fascinating article! It’s interesting to see the benefits of AR being applied to search functions in storage. As a past user of AR in military contexts, I can attest to the usefulness of this technology for target identification and navigation. The increase in situational awareness yields significant advantages, particularly in dynamic situations where speed and ease of use are of the essence. As for the future of logistics, I see a trend toward moving humans exclusively to central nodes for decision making. I also see interesting opportunities for drones to complete much if not all last-mile delivery tasks.

Fascinating read! While there is no question that AR improves the efficiency of a human working in a warehouse, I question whether AR+human in a warehouse will be obsolete even before it gets widely adopted. If AR can generate such great savings by making a mistake prone and inefficient human more efficient, complete automation could eliminate the need for human involvement and drive greater efficiency and accuracy and thus even great savings. Robots and full-scale automation are already being deployed in warehouses(1). Therefore, use of robots and automation appears to be a more compelling investment than AR+human for any warehouse operators making an investment to optimize their operations.

(1) https://qz.com/952240/righthand-robotics-has-automated-a-new-type-of-warehouse-work-that-could-help-amazon-amzn/

A very well-written, organized, and argued essay! Several questions come to mind when reading this case. While AR is no longer considered “new”, the technology has not yet moved into a mature phase where the technology is produced widely and at very competitive prices. While implementing these technologies seem to improve efficiencies in the short and long term, I wonder how capital intensive this efficiency improvement strategy actually is. While it is important to stay ahead of the competition, I wonder how investments in the technology and inevitable reduction in costs that will be realized in the next 1-3 years, make it more palatable to institute hand-held digital root-optimizing solution in the short term and incorporate AR into the process flow in the medium term. The trade off between technology and implementation costs with efficiency improvements is one every logistics business needs to face, and perhaps for some companies investing in AR solutions now may make the most sense.

Really interesting article Jas! I wrote about a courier/logistics company that’s also automating its warehouses and plans to use AR to assist its workers in the way you described. I find myself agreeing with Sergio though, if I was betting on the questions you asked, with the rapid development of AI and machine learning, it’s only a matter of time when at least these repetitive and easy but time consuming tasks are performed completely by robots/machines.