Adidas Lives its Slogan, Impossible is Nothing, with 3-D Printed Sneakers

With its new Futurecraft 4D sneaker, Adidas is striving to become the world’s biggest producer of 3-D printed products.

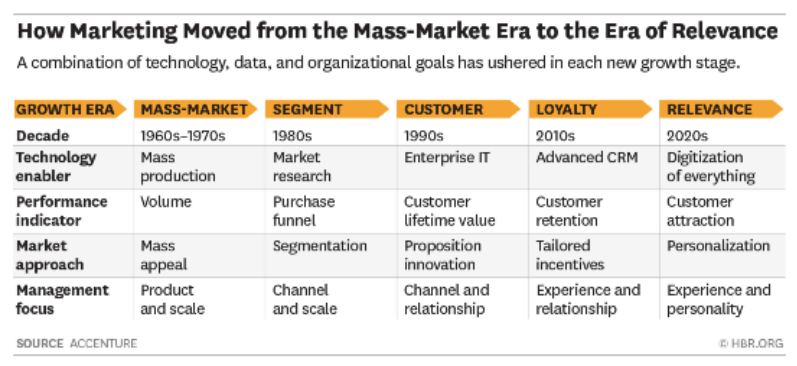

Retailers must Rebound. The retail industry has seen a lot of disruption, particularly with the rise of e-commerce. The “Amazon Effect” is frequently credited with having normalized a “frictionless shopping process with near-immediate results” [1]. Customer expectations for the speed and quality of service are amplified; demand for personalized products and shopping experiences is growing, too. As the chart below demonstrates, traditional retailers must evolve their business strategy in order to remain competitive.

Is 3-D Printing the Solution? The appeal of 3-D printing – or additively fabricating a physical object from a 3-D digital model – is primarily two-fold in the retail space. First, it promises to enable the “mass customization” of products. 3-D printing can be used to fulfill low-volume orders in a cost-effective manner, facilitating a shift from “economies of scale” to “economies of one” [2]. Second, 3-D printing technology can streamline the supply chain. Products can be made-to-order as demand is actualized, allowing retailers to hold (and ultimately discount) less inventory. 3-D printing does not require the costly custom molds used in traditional manufacturing. Plus, 3-D printing facilities can be setup close to the customer, improving delivery speed and reducing shipping costs [3].

In reality, though, 3-D printing has remained largely unproven in the retail space because of basic limitations. Layer-by-layer printing is a relatively slow means of manufacturing and is only compatible with a narrow range of materials. Further, if the printing process is not constant and automated, cost efficiencies can be lost [4].

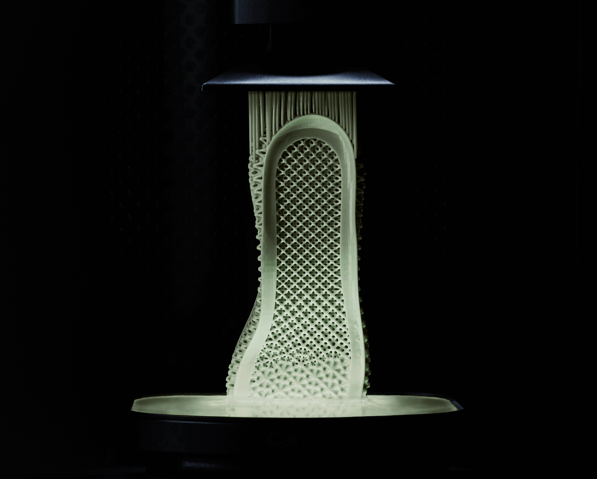

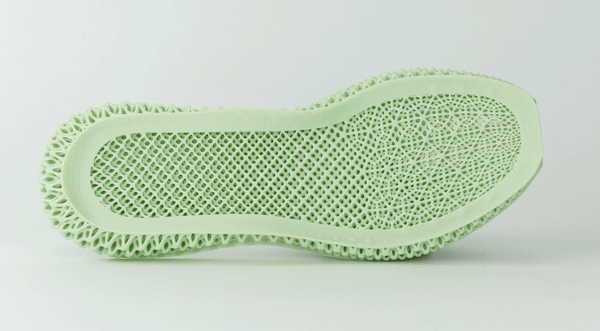

Adidas Finds a Way. Sportswear retailer Adidas has made a significant strategic commitment to 3-D printing, with ambition to be “the world’s biggest producer of 3D printed products” [5]. Adidas’ Futurecraft 4D sneaker, 100,000 units of which will be released this year, features an ornate, lattice-structured midsole constructed via 3-D printing [6]. The key to Adidas’ claim that it can use 3-D printing in a profitable and scalable way? A partnership with the Silicon Valley startup called Carbon.

Carbon, with a current estimated valuation of $1.7B, purports to have developed a technology with “night and day” advantages over traditional 3-D printing [7]. Carbon uses a photochemical process that effectively extracts the desired structure (per digital specifications) as a single piece from a pool of UV-curable liquid resin. This style of 3-D printing produces more structural integrity than the standard layer-by-layer approach, and can be executed at 100 times the speed [8]. Importantly, because Carbon’s mission is to support large-scale manufacturing, the hardware units within its 3-D printing system have been designed such that the production of 3-D objects can be highly automated [9].

Figures 2 and 3:

Presently, Adidas is busy marketing its innovative sneaker line and reorganizing its supply chain to capture the value of 3-D printing. Because the demand for printed midsoles is expected to come from Western countries first, the manufacturing of these sneakers will not happen in Asia per usual. Instead, Adidas opened a new local facility, called the “Speedfactory,” in Ansbach, Germany and equipped it with Carbon’s printing machines. Adidas has plans to open another facility in Atlanta soon [10].

In the medium term, Adidas expects to scale up production of its Futurecraft 4D sneaker to millions of units per year [11]. This is where Adidas can begin to fulfill its ultimate vision, and take advantage of the capacity for product customization. Going forward, the idea is to use 3-D printing for personalized midsoles with varying levels of density and elasticity to match each customer’s preference for support and performance. And while customers today are accustomed to paying a premium and waiting several weeks for customized sneakers, Adidas envisions a future where printed midsoles are affordable and delivered in under a week [12].

Potential Pitfalls for Adidas. It should be cautioned that many unknowns remain, including the cost of this project as it grows. Adidas would be well advised to monitor the cost drivers of production. For example, as Adidas pursues additional customization of its midsoles, the pre-printing costs could rise (e.g. skilled labor to design and review digital 3-D specifications). Or, Carbon might go public and change the pricing model for leasing and servicing its 3-D printing machines. Adidas could also find that the yield of the Carbon 3-D printers drops as they are pushed to a higher utilization.

What do you think? There is a lot of hype for the Adidas Futurecraft 4D sneaker – it represents a compelling retail use case for 3-D printing. Still, skeptics will argue that 3-D printed sneakers are chiefly being used by Adidas for brand marketing, suggesting that the real value is in “the kind of halo that the chess-playing computer Deep Blue brought IBM” [13].

Is the Futurecraft 4D sneaker a glimpse into the future of manufacturing? Will 3-D printing be an enduring technological innovation in the retail space? Or is the value, here, in the novelty and marketing potential?

Word Count: 797

Sources

- Grosman, Lin. “What The Amazon Effect Means For Retailers.” Forbes, February 22, 2018, forbes.com/sites/forbescommunicationscouncil/2018/02/22/what-the-amazon-effect-means-for-retailers/#6ccdba482ded, accessed November 2018.

- Brown, Alan. “Chain Reaction: Why Additive Manufacturing is about to Transform the Supply Chain,” Mechanical Engineering 140, no. 10 (October 2018): 30-35.

- Sodhi, ManMohan S., and Christopher S. Tang. “Supply Chains Built for Speed and Customization.” MIT Sloan Management Review, June 06, 2017, sloanreview.mit.edu/article/supply-chains-built-for-speed-and-customization, accessed November 2018.

- Bourzac, Katherine. “Carbon Prints Amazing Materials.” MIT Technology Review, June 27, 2017, https://www.technologyreview.com/s/607964/carbon-prints-amazing-materials, accessed November 2018.

- Cheng, Andria. “How Adidas Plans to Bring 3D Printing to the Masses.” Forbes, May 22, 2018, https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#29f4813e4a60, accessed November 2018.

- Ibid.

- Ibid.

- Caliendo, Heather. “3D Printing, Silicon Valley Style.” Plastics Technology, October 31, 2018, https://www.ptonline.com/articles/3d-printing-silicon-valley-style, accessed November 2018.

- Carbon, https://www.carbon3d.com, accessed November 2018.

- Sodhi and Tang, “Supply Chains Built for Speed and Customization.”

- Cheng, “How Adidas Plans to Bring 3D Printing to the Masses.”

- Sodhi and Tang, “Supply Chains Built for Speed and Customization.”

- Sodhi, ManMohan. “3-D Printed Sports Shoes are More About Your Wallet Than Your Feet,” Rockaway (November 2017).

Figure 1 Source: Zealley, John, et al. “Marketers Need to Stop Focusing on Loyalty and Start Thinking About Relevance.” Harvard Business Review, April 23, 2018, hbr.org/2018/03/marketers-need-to-stop-focusing-on-loyalty-and-start-thinking-about-relevance, accessed November 2018.

Figures 2 and 3 Source: https://www.carbon3d.com

Interesting article! I had no idea how much retail was getting into the 3D printing business. You bring up excellent points about issues with scaling, especially in regards to more personalized products. I am personally on the thought train that this is a marketing ploy. But hey, you have to make yourself stand out somehow!

Is it comfortable? 3-D printing has many interesting uses, but I am skeptical of a 3-D printed shoe being a high-performance or comfortable alternative to traditional methods. Shoe companies should strive to offer their customers the most cutting-edge technology, but performance should be the number one priority. Until Adidas proves that the benefits of this new technology either outperforms the existing technology or is substantially cheaper than the status quo, I will not be a buyer. Additionally, how has Adidas been a victim of the “Amazon Effect?” Shoe stores like Finish Line or Foot Locker have faced challenges as Amazon’s market share has grown, but people are still buying shoes and Adidas shouldn’t be materially affected by where they are purchased as long as they are buying Adidas.

I have two different perspectives this interesting article. First, 3D printing might be great for innovation, as it fastens the process of prototyping. However, for mass production, I do not think it should be widely used. Copying has been a big problem for apparel industry as mentioned by Adidas CEO [1]. With improving reverse engineering capabilities and 3D production capabilities, Adidas can be perfectly copied by low cost producers in the markets and with new capabilities, these low cost producers would be able to hit even the quality level of Adidas. Second, even if Adidas wants to invest in 3D printing, cyber security should be their number one priority. Would you imagine that designs of Adidas shoes are stolen and go public? For an sports apparel company, I am not sure whether it makes sense to invest significant amount of money to cyber security.

[1] https://www.cnbc.com/2018/05/03/10-percent-of-adidas-products-in-asia-are-fakes-ceo-says.html

Great piece!

Clearly, 3D printing stands to disrupt retail in immeasurable ways. It seems smart for Adidas to invest in this technology, but the question presented by the author about Carbon’s ability to later change its pricing/business model seems really significant. Once Carbon or another 3D printing company figures out how to produce sneakers at scale, i don’t see why this wouldn’t level the playing field for all shoe companies. How should companies create a strategy for the future, assuming 3D printing becomes a reality, to remain competitive? For an apparel company like adiddas, won’t their design and brand equity remain the most important value add?

This is a really interesting piece! I’d be interested to see what the brand equity value of 3D printing is for Adidas going forward. The ability to instantly customize shoes for elite athletes and eventually for the mass market could really help Adidas establish itself as an innovative sportswear company (similar to what we saw with Nike Football in our marketing case this week).

Hi KO, I loved this article.

To your question: “Will 3-D printing be an enduring technological innovation in the retail space?”. To me it’s unclear when it will happen, but my bet is that it will be so, especially in the apparel space. I think this because people have really different body sizes and styles, yet today most of us have to buy from the 4 or 5 sizes that each product comes on. If Adidas is able to customize clothing to my exact body shape and preference, it will have a huge advantage over its competitors. I can imagine going once to a store, getting my measures taken and then just ordering online the designs that I like and have them made to fit exactly to me.

I think they did a fantastic job by partnering with a cutting edge startup working on the space, and should consider acquiring them given the huge market potential of this initiative.

Loved this article! I liked your point about being able to print the merchandise closer to the consumer to improve the delivery speed and reduce the shipping costs – I hadn’t thought about that benefit. Even further out, wouldn’t it be amazing if you had a local 3D printer you could go to for anything you need or have it sent to you immediately? Seems like Amazon’s dream…

But on that Amazon thought, I agree with the post above that Adidas should be somewhat concerned about copycats in the 3D printing space. I assume they would protect themselves by using and publicizing “patented” materials that typical consumers could not access (even if consumers could access a similar design).

I also agree with your point about the move towards customization. Though customization of products sounds great in theory, I wonder how much customization we really need. That is to say, how much incremental benefit does a shirt or shoe perfectly designed for you actually provide vs your standard size, in one of a million different models available on the market? I’m not convinced it’s that much!