Adidas Futurecraft 4D: One shoe to rule them all?

Can Adidas harness technological advances in 3-D additive manufacturing to build the shoe of the future and overtake Nike as an industry leader?

For the past two decades Nike has absolutely dominated the global athletic footwear market. With roughly 35% of a $64 billion market that is expected to grow at a Compound Annual Growth Rate of slightly over 5% from 2018 to 2025 [1] – Nike sits in a dominate position. Nevertheless, Adidas has recently taken market share from Nike, doubling its 2016 share of 6% to 12% in 2017 [2]. It’s focus on scale, online presence, and success in recognizing trends are just a few reasons behind its’ surging performance [2]. With a look towards the future, Adidas is investing in 3-D additive manufacturing to produce the footwear that may just unseat the market heavyweight that is Nike.

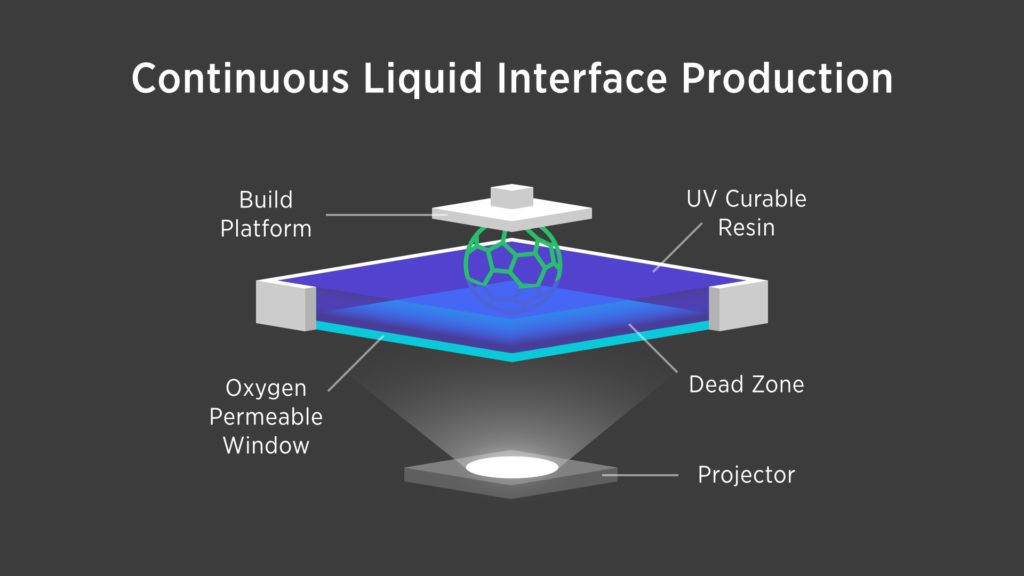

In order to do so, Adidas is in investing heavily in 3-D printing through a partnership with Silicon Valley based startup Carbon. Carbon uses a form of 3-D printing, or additive manufacturing, that it calls “Digital Light Synthesis (DLS)” – a method of continuous liquid interface production. Unlike traditional 3-D manufacturing which overlays two dimensional layers of material on top of each other to create a three dimensional product, DLS uses light and oxygen to make plastic objects like sneaker mid-soles from a pool of resin without waste or a need for injection molding [3]. The 3-D printer receives input from cloud based software that can be easily customized. Ultimately, this technology can scan consumers feet in stores, gather data about their gait, and deliver personalized shoes in a printing process that is “100 times faster” than the roughly 24 hours required of traditional 3-D shoe printing utilized by competitors like Under Armour [4]. While it is difficult to compete with traditional manufacturing on scale, 3-D printing has a massive advantage when considering the cycle time of design, prototyping, production, and delivery. If a completely new shoe design is desired the cycle time required for design, prototyping, testing, manufacturing, and shipping can push design to delivery time on the order of 15-18 months [3].

The benefits of additive manufacturing go well beyond the custom fit shoe creation and improved cycle times. Shoe manufacturers traditionally look to low cost of labor markets like Asia to source the manufacturing of its shoes. In fact, Adidas sourced 68% of its shoes from Asian manufacturing centers in 2016 [5]. Carbon’s 3-D printer will allow Adidas to relocate production plants from Asia, to more advantageous distribution locations that can provide just in time manufacturing and a quick customized response.

Adidas manufactured roughly 5,000 pairs of its $300 Futurecraft 4D shoe with Carbon in 2017 and officially announced a formal partnership in April of 2018 [6]. It plans to produce 100,000 pairs of Futurecraft 4D by the end of 2018 and is beginning to shift 3-D shoe production to a factory near Adidas’s headquarters in Herzogenaurach, Germany as well as out of Carbon’s silicon valley plant. While the specifics of Adidas long-term plan are purposefully vague, the goal is to make a uniquely customized shoe that is manufactured and delivered in a fraction of the cycle time required by traditional shoe manufacturing.

It should not come as a shock that the 3-D footwear space is hotly contested. Both Nike, New Balance, and Under Armour are producing shoe models specific to elite level sports performance in soccer, baseball, and cross training. Because of the low barriers to entry, Adidas needs to ensure it markets the shoe and its process to the right consumer and solidify its “mind share” in the “future of footwear” market. In this case, Adidas should focus its activities on serious amateur athletes and those with unique foot related issues that would be ideal initial customers for a premium margin product.

Despite its potential, questions remain about Carbon’s proposed shoe manufacturing technology. Traditional additive manufacturing can cause products to be inconsistent on a molecular basis and therefore structurally weak in a particular axis [7]. Carbon claims to avoid this weakness due to its “Digital Light Synthesis” production process that builds from a pool of resin vice a layered additive approach. Despite that difference, questions remain. Can the shoe hold up to the wear and tear of dynamic activities involving quick start and stop or cutting motions? Will the resin used in the process remain durable in the face of the elements and the variety of chemicals found on a run through an urban landscape? And finally, will there be enough buyers of this high margin product to make a significant dent on Nike’s market share?

Source: Adidas

Source: Adidas

(word count: 735)

[1] Roberts, Daniel. “Adidas Has Nearly Doubled its US Sneaker Market Share – At Nike’s Expense.” finance.yahoo.com, 23 Jun. 2017, https://finance.yahoo.com/news/adidas-nearly-doubled-us-sneaker-market-share-nikes-expense-153106743.html

[2] Chin, Kimberly. “Adidas has found a way to ‘fully exploit’ its online opportunity — and it could make a killing.” Business Insider, 19 Jan. 2018, https://markets.businessinsider.com/news/stocks/adidas-stock-price-has-found-a-way-to-fully-exploit-its-online-opportunity-and-it-could-make-a-killing-2018-1-1013326915?utm_source=markets&utm_medium=ingest

[3] Cheng, Andria. “How Adidas Plans to Bring 3D Printing To The Masses” Forbes, 22 May 2018, https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#658663a14a60

[4] Garfield, Leanna. “Under Armour 3D-printed soles for its new $300 sneakers with powder and lasers” Business Insider, 1 Jul. 2016, https://www.businessinsider.com/under-armour-3d-prints-its-new-architech-shoes-2016-6

[5] “Supply Chain Approach” Adidas, https://www.adidas-group.com/en/sustainability/compliance/supply-chain-approach/#/aufbau-der-beschaffungskette/

[6] “The perfect fit: Carbon + adidas collaborate to upend athletic footwear.” Carbon, 7 Apr. 2018, https://www.carbon3d.com/stories/adidas/

[7] B. Roca et al., “Getting past the hype about 3-D printing” MIT Sloan Management Review58, no. 3 (Spring 2017): 57–62.

In response to your last question, I really believe that this is going to be how things are manufactured in the future. Especially in industries where things like shoes or clothes can be tailor made to fit you, perfectly and specifically. These shoes are currently somewhat expensive, but pro-athletes or those from a more upper class background might find it well within their reach to be early adopters of this product, and therefore make some sort of a dent in Nike’s market share. Price might be a lever they could eventually play with to win some market share if they can reasonably scale up their operations without taking too big of a bet on this (currently) niche product.

The shoe itself looks incredible and I have no doubt it will capture the market quickly until competition catches up. Nike itself is testing out and close to launching its own flyprint shoe (https://news.nike.com/news/nike-flyprint-3d-printed-textile), which is also a remarkable piece of manufacturing. I wonder if Adidas itself is convinced about the shoe’s stability and ability to hold up to wear and tear. Every iconic launch of its product (especially shoes) is by an athlete, either through use or through an advertisement campaign. This deviation to launch the product on a standalone basis make me wonder if they were unsure if sport stars would consume the shoe. The fact that the 3D printing results in inconsistencies in output for any given input could be concerning for pro-athletes, and they would rather stay with the traditionally manufactured shoes until this process is perfected. That would mean that the shoe for now only provides “style” value or “fashion” value and its sale may be restricted to that audience. Competitors may catch up to the sales by then and so it is imperative that Adidas continues to invest in perfecting the product because I too believe this is the future of shoes.

To provide a thought on your second question — I think a market that will be very happy with this made-to-order, good quality shoe are people with different sized feet! While most people have feet of slightly different sizes (see sources such as [1] and [2]) for some it’s more significant than others either because the size difference is large or because they play a sport where fitting into your shoes/boots perfectly is important for performance (even at college level for example). Most people just end up buying a size to fit the larger of their feet (though a small minority have to go to the extent of buying two different pairs of shoes [1]). If these folks had the option to buy one pair of shoes that fits both feet well I imagine they’d be very happy, and become repeat buyers. While it may not be a daily pain point that people contemplate, reminding these folks of their different sized feet and providing this exciting solution could be an unusual and untapped market!

Sources:

[1] https://corewalking.com/one-foot-bigger/

[2] https://www.indiatimes.com/health/healthyliving/are-your-feet-two-different-sizes-242389.html

It’s interesting to learn how Adidas is capitalizing on 3D printing to get innovative products to market in shorter lead times than any of the competition. I can see this making a significant impact on the Adidas’ ability to gain market share and potentially displace Nike. If Adidas’ quality can keep up with consumer expectations, the next hurdle the business will face is keeping up with demand. Overall, Adidas has some large hurdles ahead, but definitely has a tool that can be used to maintain a competitive advantage and gain increased relevance in a competitive market.

I’m actually most concerned about your first question – how can this 3D printed shoe be the most functional when it comes to athletic competition? What Adidas and Nike are selling is meant to be functional. If the sneaker is not viable for basketball, say because it lacks stability required for ankles, or for running, because it lacks cushioning in the sole, then what demand will there be? Athleisure is a fashion trend that Nike and Adidas have benefitted from recently, but investing this much in product innovation for a product that can’t even be used in a sport? I think that is a risky departure from the company’s purpose and mission.

Regarding your 3’rd question, I think that this is the main issue, the ridiculously high price of the shoe will deter almost every customer to even try it, until the price drops significantly it will face a major challenge in persuading customers to buy them without any additional value. Therefore, a stronger emphasis needs to be on reducing the cost, maybe even consider selling at a loss until they can reach scale to support a much lower price?

Also, If the company could create more value than just perfect customization, I think that it could position itself to sell the shoes with the higher price tag to professional athletes who would value performance much over price.

Loved reading this article, especially right after reading about Nike’s own 3D printing endeavors from Alexandra’s post. I had not even considered the fact that 3D printing might enable for manufacturing to come back to the US, or just closer to where the products are actually sold. I think this could be HUGE! Not only will there be a reduction in cost, with less transportation cost, but there might also be a qualitative/emotional cost when it comes to people knowing there product was made right there. I can’t even imagine going into an Adidas store in Panama, getting my feet sized, and getting shoe printed right there. In my opinion this experience would definitely give an edge to Adidas over other shoes. That said, I think if the quality is not there, everything else is irrelevant. Adidas will need to make sure that the 3D printed elements actually hold the same quality.

My hypothesis is that as the 3D printing hardware evolves, so will the materials that are used to print shoes. I think the new materials could even be more durable than those of today. New techniques can be developed to “weave” a shoe vs glue pieces of a shoe together. I also wonder whether 3D printing could be used to repair shoes as well. As far as the demand, I think the mass market appeal of 3D printed shoes will be from customization and style, not performance. Given that Nike and UA are also investing in this area, Adidas needs to continue investing in technology to be competitive.