Additive manufacturing and the future of Nike

Nike Mission Statement: To Bring inspiration and innovation to every athlete in the world (if you have a body you are an athlete).

Nike is the largest seller of athletic footwear and apparel in the world. The industry is highly competitive, with Adidas, New Balance, Puma, and Under Armour being frequently sited key competitors of Nike. These players competed on the design, development, marketing and selling of athletic footwear, apparel, equipment, accessories, and services.1

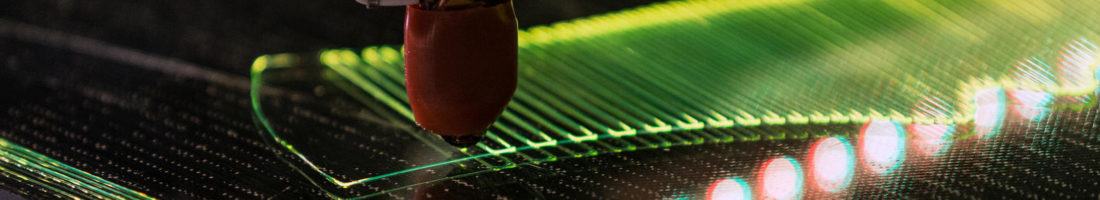

Additive manufacturing (also known as 3D printing) is a method of translating a digital design to produce physical objects by adding successive think layers of materials. It poses 4 sources of competitive advantage for Nike:

- Easier product development and testing, since additive manufacturing allows for fast iterations of design

- More efficient production process, from flexibility to implement design changes, reduced waste of materials, and ability to produce locally instead of having to centralize production in low cost locations (reduced waste and carbon footprint also fit with the company’s zero waste pledge and Considered Index)2

- Better quality of products, as 3D printed shoes could be better fitting, more durable, and lighter

- Ability to customize, since unit cost of making a single piece or many is about the same, and new additive manufacturing technological advances now allow for minor design tweaks without changing global (overall) design of a product

Current state

Historically, Nike and its competitors have used additive manufacturing in their prototyping process. The application to mass production was limited due to high cost and the fact that it took two hours to 3D print a single sole in 2013.3 This changed in 2015, when competitors New Balance and Adidas launched limited-edition shoes made with 3D printed midsoles.4 In the following years, Nike explicitly make additive manufacturing a core part of its strategy. In its 2017 analyst call, CEO Mark Parker commented: “we’re continuing to scale our transition from cut and sew, where precision is at the stitch level, to digital design, where precision is at the pixel level.” The goal is “getting product to the consumer faster. It’s about lowering our product cost, as we talked about, really trying to drive greater labor productivity, less waste in the system, new design capabilities.”5

Nike partnered with various 3D printing companies, including HP and ProdWay, and in 2018, launched Nike Flyprint – the first 3D-printed textile upper in performance footwear. The benefit was multitude: Nike was able to prototype with Flyprint 16 times faster than in any previous manufacturing method; the shoes are lighter and more breathable due to increased interconnection between parts; and it was able to translate athlete data directly into textile geometries.6

Medium term speculation

Going forward, Nike saw the technology a key component in increasing the “speed to market”, as well as a source of potentially longer-term benefits including customization for tailor-made footwear solutions.7 According to additive manufacturing consultant Alan Guyan, the opportunity of additive manufacturing is in customization, beyond efficient manufacturing, and all of the leading footwear companies are investing in customizable programs. 8 A key challenge is to ensure that design is not compromised for anatomical fit, since design is still the key driver for customer purchasing decisions.9 Therefore the companies need to decide on the parts of designs that are most valuable for customization and least susceptible to design compromise. (primary research) James Carnes, VP of strategy creation at Adidas further suggested that, making additive manufacturing fully-customized requires the cost of material to further decrease.10

Recommendations

Given the potential additive manufacturing has on manufacturing efficiency, product quality, speed to market, and general brand equity of Nike, it should consider going further than relying on partnerships with specialty additive manufacturing technology companies, and develop proprietary technology and methods in-house.

In the long term, Nike could also use similar technology to prototype and produce its other products, including apparel, equipment, and accessories. Shoes have seen more application of additive manufacturing since the material (resin or power) and design (organic, stable shape) of soles are more conducive to the technology. However, recent advancement in additive manufacturing allows it to be used with other materials, and have more variability in design.11

Open question

If Nike uses additive manufacturing to customize its shoes for customers based on customers data, would it diminish the value of design? Nike has a brand built around the tradition of building each design for a star athlete, would this become obsolete as each pair of shoes is now made for a specific customer? What does Nike need to do to proactively manage its brand, value proposition, and relationship with those star athletes?

(743 words)

References

- NIKE, Inc. Form 10-K, 2018. https://s1.q4cdn.com/806093406/files/doc_financials/2018/ar/docs/nike-2018-form-10K.pdf.

- Kell, John. “Nike Now Uses Recycled Materials In Most Of Its Gear.” May 11, 2016. http://fortune.com/2016/05/11/nike-recycled-materials-gear/.

- Jopson, Barney. “New stamping ground for Nike and Adidas as 3D shoes kick off.” Financial Times. June 9, 2013. https://www.ft.com/content/1d09a66e-d097-11e2-a050-00144feab7de.

- Allen, Rachel. “Adidas Launches 3D-Printed Performance Footwear.” Footwear News. October 9, 2015. https://footwearnews.com/2015/focus/athletic-outdoor/adidas-futurecraft-3d-printed-sneakers-technology-photos-161298/.

- NIKE, Inc. FY 2017 Q1 Earnings Release Conference Call Transcript. https://www.sec.gov/Archives/edgar/data/320187/000032018716000376/a8-kq1fy17erccexhibit9911.htm

- “What is Nike Flyprint?” Nike News. April 17, 2018. https://news.nike.com/news/nike-flyprint-3d-printed-textile.

- Chochrek, Ella. “Nike Is Getting Into the 3D Printing Game.” Footwear News. June 7, 2017. https://footwearnews.com/2017/focus/athletic-outdoor/nike-3d-printing-sneakers-prodways-368238/.

- Primary research: interview with Alan Guyan, Director of Design & Manufacturing Innovation at Under Armour, Guest Speaker at Additive Manufacturing User Group and IMTS International Machine Tool Show.

- Spahiu, Tatjana. “3D Printing as a New Technology for Apparel Designing and Manufacturing.” International Textile Conference. November 2016.

- Cheng, Andria. “How Adidas Plans To Bring 3D Printing To The Masses.” May 22, 2018. https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#1ed543af4a60.

- R Melnikova, A Ehrmann and K Finsterbusch. “3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials.” IOP Science.

Awesome article. The move to 3D print manufacturing is definitely a positive one. I don’t see it detracting from Nike’s design-focused brand. Consumers are still going to want the same colorways that LeBron & Serena are wearing on the court. The only thing that might change is that there will be fewer purchase returns due to a better-fitting shoe. Since their main focus right now is arguably increasing their speed to market, they should invest in proprietary 3D technology. Nike needs to make sure that they’re still shaping the global conversation around sports culture, and one of the best ways to do that is to be first to market with their innovations.

Love the article! Wanted to comment on your recommendation for Nike to develop its own additive manufacturing technologies, instead of relying on partnerships. I agree that it would be a smart strategic move, and one to consider as an aspirational goal for the future – but as it stands now, many companies don’t want to invest the money into owned technologies until the entire field becomes more advanced. [1] I think until technology develops further, brands like Nike will not be able to source the capital to invest.

[1] “Google Moon Shot could Give Industrial 3D Printing a Boost.” Industry Week, 2017, ABI/INFORM via ProQuest, accessed November 2018.

Elizabeth – terrific article. One point that stood out to me was around the potential for 3D printing not only to help customize shoes and lower manufacturing costs, but also for it to aid with Nike’s goal of reducing environmental impact. Once additive manufacturing is better proven and cheaper, I agree with your recommendation that Nike should invest heavily in the space. Increasing customization, reducing costs, and lowering carbon footprint are all high priorities for the company that can be elegantly solved through this technology.

Interesting article! I agree that 3D printing / additive manufacturing can give Nike an even greater edge over its competitors through more efficient and quality-controlled production. I believe another key area in which Nike could leverage the faster product development is by doing quicker tests of how some of their newer products fair in the market. It could help them more efficiently test the viability of new products on a small sample size and gain quicker insights and data on how to improve their offerings.

The potential in additive manufacturing for Nike is enormous!

Great article – it’s a very interesting application of additive manufacturing. While I agree with the article and the comments in the benefits and potential of additive manufacturing for Nike, I also have some concerns about how its implementation can negatively impact Nike’s value proposition:

– Nike invests millions of dollars in designing shoes that support the perception of the brand from the mass. With additive manufacturing, consumers could be able to personalize its designs – potentially leading to designs that harness Nike’s brand. One illustrative example could be the inclusion symbols that are offensive in the shoes. How will Nike keep control of every design of their shoes?

– Additive manufacturing allows for local production. As the technology evolves, potentially local businesses and even consumers could own additive manufacturing technologies themselves. Could local business and consumers bypass Nike and produce the shoes themselves?

Great points, Josep. I think the way that Nike controls the design and the product messaging is to put limits around the customization. Customization should be around color schemes, or fit on a foot i.e. amount of arch a shoe has, initials; what the customization should not include are changes to the fundamental design or symbols, etc. I wonder if there is a way to flag potentially offensive signs as well.

Elizabeth, as for your question around athletes, I agree with Emma’s points. Lebron and Jordan fans will continue buying their favorite sneakers as they have a connection with the player and their brand. Nike will still be able to lead with its shoe and athletes for lifestyle shoppers, where I see the customization and 3D printing really making a difference are for those athletes within ourselves searching for performance.

Amazing article! I am more excited to see the use case of 3D printing that Nike will use in the future. I think Nike should have a control on design, but use 3D printing as a customization for the better fit on a foot. Also, Nike can utilize additive manufacturing to pilot their products in the market faster than before. I wonder how other sports industries are using additive manufacturing as a means of improving their process and design, and how Nike can go step further by using additive manufacturing as their competitive edge.

Very interesting read! I found it intriguing that Nike is using 3D printing to meet the needs of the every changing sneaker fashion. However, I do worry that once this becomes common practice that Nike’s competitors will begin offering custom sized shoes (or the consumer will). This could really drive the prices up for Nike as a company.