AB InBev: Brewing Initiatives to Fight Climate Change

AB InBev’s climate change challenges, and the innovative initiatives to combat them.

Wait – not our beer?

Breweries are already being affected by climate change, and the effect is likely to increase in coming years. Producing a product that consists of mostly water, using water-intensive crops and energy, and then shipping it all over the world is going to have a pretty considerable impact on the environment. And when you’re the company producing 457 million hectoliters of it per year, you’re going to be a little worried[1].

Formed upon the 2008 merger of Anheuser-Busch and InBev, AB InBev is the world’s largest brewer by a large margin. With $43.6 billion in revenue in 2015, the company operates in over 50 countries and sells its products all over the world[2]. Its brands include favorites like Budweiser, Corona, and Stella Artois. Producing beer at such massive quantities has obvious implications on the environment, and company of this scale would clearly be concerned about in terms of consumer perception, impact on the bottom line, and broader corporate social responsibility.

Water is perhaps the most obvious issue they face. It takes an average of 5 barrels of water to produce 1 barrel of beer[3]. In a world where water shortages are affecting communities all over the globe, consumers are increasingly becoming conscious of products that consume large amounts of this resource. The importance of consumer perception is clear to AB InBev – just visiting their website one quickly notices one of their six home navigation tabs is labelled “Better World”, dedicated to sustainability.

Beyond perception, there are also very real economic implications that climate change will have on the company. More frequent and severe droughts are being attributed to climate change today, which impact the raw materials AB InBev relies on. US production for hops, a key raw material for beer, is concentrated around the western part of the country– with 91% coming from Washington, Oregon and Idaho[4]. The drought in the western states has become a severe problem for a crop that can demand large amounts of water. This has the potential to result in a crop shortage and increase prices. Barley, the other agricultural input to beer, is experiencing the same water shortage problem.

AB InBev is keenly aware of these issues, and already working on solutions. Through Voyager Plant Optimization (VPO), their operations management system, they’ve built in environmental incentives deep into their processes.[5] Their commitment includes compliance above the legal standards, incorporation of environmental targets in performance evaluations, and accountability at the individual level[6].

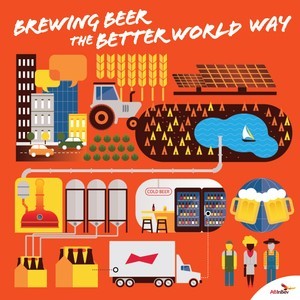

(Image Credit: AB InBev[7])

They also have developed specific initiatives: Their Global Barley Research program aims to create more efficient barley cultivation, with goals of up to 40% less water usage[8]. They also have irrigation research projects with similar goals underway, and have developed a network of weather stations called AgriMet in order to provide farmers with information that can help optimize their water usage[9]. Among their corporate social responsibility projects, they started a campaign in partnership with Water.org that provided about 800,000 people with clean water[10], in addition to a project to preserve important river basins in Brazil [11].

Of course, there’s a lot of work ahead and additional opportunities to be pursued. One option would be to work with farmers to incentivize the diversification of US hop growing to other states. This could help reduce the strain on the west and allow water to be diverted to other crops, while mitigating the risk of a shortage in the face of a drought. They could also invest in new crop yield technologies. An example would be working with a cutting edge research firm like Indigo Agriculture to leverage microbiomes in increasing efficiency. Additionally, there’s the option of contributing to longer term sustainable water sources. Water shortages are likely to be a major problem on a global scale going forward, so larger scale technologies like water desalination could be a good investment for the future.

AB InBev’s aggressive Environmental Policy closes with the following line: “Neither production goals nor financial objectives shall excuse non‐compliance”[12]. Let’s hope to see more companies adhering to this principle in the coming years.

(Word Count: 678)

[1] Statista. 2016. Production volume of Anheuser-Busch InBev worldwide, 2015 | Statistic. [ONLINE] Available at: https://www.statista.com/statistics/269111/production-volume-of-anheuser-busch-inbev-worldwide/. [Accessed 03 November 2016].

[2] Reuters. 2016. AB InBev plays down talk of move beyond beer | Reuters. [ONLINE] Available at: http://www.reuters.com/article/us-abinbev-m-a-idUSKCN0XO1Q7. [Accessed 03 November 2016].

[3] Justin Solomon|CNBC Producer. 2016. How Much Water Does it Take to Make Beer? . [ONLINE] Available at: http://www.cnbc.com/id/39381417. [Accessed 03 November 2016].

[4] EcoWatch. 2016. Climate Change Poses Threat to Key Ingredient in Beer, NOAA Warns – EcoWatch. [ONLINE] Available at: http://www.ecowatch.com/climate-change-poses-threat-to-key-ingredient-in-beer-noaa-warns-1882168560.html. [Accessed 03 November 2016].

[5] Embedding sustainability | AB InBev. 2016. Embedding sustainability | AB InBev. [ONLINE] Available at: http://www.ab-inbev.com/better-world/embedding-sustainability.html. [Accessed 04 November 2016].

[6] AB InBev. 2014. AB InBev Environmental Policy. [ONLINE] Available at: http://www.ab-inbev.com/content/dam/universaltemplate/ab-inbev/Better%20World/ABI_Responsible_Environmental_Policy_2014.pdf. [Accessed 3 November 2016].

[7] AB InBev, (2016), Brewing Beer the Better World Way [ONLINE]. Available at: http://admin.csrwire.com/system/press_release_images/38916/normal/AB_InBev_Better_World_value_chain.jpg[Accessed 3 November 2016].

[8] AB InBev. 2015. 2015 Global Citizenship Report – Working Together for a Better World. [ONLINE] Available at: http://www.ab-inbev.com/content/dam/universaltemplate/ab-inbev/sustainability/document.pdf. [Accessed 4 November 2016].

[9] AB InBev. 2015 Global Citizenship Report – Working Together for a Better World.

[10] Stella Artois and Water.org Buy a Lady a Drink. 2016. Stella Artois and Water.org Buy a Lady a Drink. [ONLINE] Available at: http://www.ab-inbev.com/media/our-stories/brands/stella-artois-and-water-org-buy-a-lady-a-drink.html. [Accessed 04 November 2016].

[11] Watershed Protection: The CYAN Movement. 2016. Watershed Protection: The CYAN Movement. [ONLINE] Available at: http://www.ab-inbev.com/media/our-stories/better-world/the-cyan-movement.html. [Accessed 04 November 2016].

[12] AB InBev. AB InBev Environmental Policy

When I think about Beer in the context of Climate Change – I instantaneously think of Water and Raw Material shortage. The Smart Barley program speaks highly of the long-term sustainability efforts of AB InBev, preventing reduction in Beer yield in the longer-run. But raw material related initiatives seem more like long-term adoption initiatives than mitigating climate change actions. Are they doing as much as they can or should in the other parts of the Value-Chain: Distribution systems (transport related emissions), Operational efficiency (electricity consumption), refrigeration at retailers, waste disposal? Though, I was pleasantly surprised to see some pioneering initiatives like the use of ‘B50’ Fuel in Argentina where their distribution trucks run on 50% Biodiesel [8]; and the use of Eco-Coolers that use gases that lead to lower GH emissions (http://www.environmentalleader.com/2016/05/13/how-ab-inbev-beat-its-eco-cooler-goal-two-years-early/). I would still like to see them putting compelling goals across their entire value-chain so that they can have a broader impact towards climate change than just focussing on water and raw materials that are primary to their industry.

After all, they’re a (mammoth) $40Billion+ revenue company.

AB InBev impacts the environment with its transportation needs, but I would imagine this effect is much smaller for the largest brewing company in the world compared to the smaller craft and microbreweries. AB InBev has over 20 breweries across the world, which allows them to distribute nationally with shorter transportation distances. (http://www.ab-inbev.com/content/dam/universaltemplate/ab-inbev/News/Press%20kit/ABI_FS16_US.pdf) AB InBev also has other benefits due to economies of scale and the ability to invest large amounts of capital in research. I hope they share the technical advances they make with the smaller breweries, who may not have the ability to find these improvements. There are over 5,000 craft breweries in the United States the distribute to various locations nation-wide, contributing to carbon dioxide emissions from transportation. (http://www.samueladams.com/our-story/)

More generally I am wondering about two trends in the industry.

As InBev’s issues focus mostly around water shortages in farming of its main ingredients may it be possible that the future for InBev lies in upstream integration. With fewer resources available can InBev, as an absolute heavyweight in the industry, develop a competitive advantage by securing supplies by directly owning and managing them. This way climate change could potentially help them to drive smaller competitors that may find it harder to do this out of the market.

Relating to this I would like to entertain the thought how these developments could drive a further consolidation of the industry both nationally but especially internationally. With weather patterns becoming increasingly unpredictable it may make sense for InBev to diversify away some of these risks spreading its breweries and sourcing activities even further around the globe.

I believe these two could be high level strategic considerations InBev needs to make beyond the above coping mechanisms.

There are so many opportunities for a vertically-integrated company like Ambev to reduce its environmental impact. As you’ve laid out very nicely in your post, the company has adopted a very proactive approach to dealing with many of these opportunities as it relates to its supply chain and distribution network. On top of those opportunities, an additional challenge that Ambev and many other CPG companies are grappling with is the need to reduce the impact from packaging materials. Ambev has made some progress in developing more environmentally-friendly packaging materials and practices, such as the development of a plastic bottle made of 100% recycled materials (https://www.google.com/search?q=ambev+environmentally+friendly+packaging&ie=utf-8&oe=utf-8#q=ambev+recycling) and a more close monitoring of raw materials the company recycles in each of its many markets (http://www.ab-inbev.com/content/dam/universaltemplate/abinbev/pdf/sr/download-center/AmBev_GCReport_1.pdf). That said, it is unclear how much of a priority packaging is in the context of the company’s overall sustainability program. I wonder to what extent the company could further its environmental efforts by setting its sights on what is undoubtedly a huge producer of waste?

Has AB InBev thought about vertical integration at all? How much do they work with and invest in hop farmers to promote long-term water efficiencies in the industry?

Also, your post mentions more efficient barley cultivation by 40%. Does this mean that the water used to produce 1 barrel of beer will reduce to 3 barrels?

This sounds similar to Corona’s high demand in the US driving water shortages around their production plant in Mexico. (https://www.theguardian.com/world/2016/jun/30/americans-beer-corona-mexico-water-crisis) This has affected the region to such an extent that there’s no water left for human consumption!

Great post. I like what AB Inbev is doing for the most part, but am worried that their partnership with Water.org is just noise. If they want to focus on sustainability, I think they can have a greater impact by tying it to their bottom line and focusing on creating shared value (HBR). I think that their efforts with VPO are headed in the right direction.

In thinking about sustainability as it relates to brewing, I wonder how the industry can find ways to incentivize microbreweries to focus on environmentally conscious brewing. Craft brew is becoming increasingly popular in the US and firms like Inbev have recently acquired smaller breweries like Stone and Goose Island. Is there a way outside of consolidation to brew responsibly?