3D Printed Teeth? Digital Dentistry (Sirona) and it’s Threat to Commercial Dental Labs

Digital dentistry has offered vast improvements in the dental care delivery system and is here to stay. While it present a looming threat to commercial dental labs, there is vast potential for them to adapt and provide additional value in the dental care delivery system.

Of all the amazing things one could imagine being 3D printed – I doubt that many would pick teeth. In truth, 3D scanning and milling in the dental industry is a well established trend in the field and is one of several digital innovations that is advancing the field of health care. While digitization in clinical dentistry has created efficiencies in the production of anatomical models, dental prostheses, and surgical guides, continued advancement of these technologies has been seen as a potential threat to commercial dental laboratories, a key partner in the clinical supply chain.

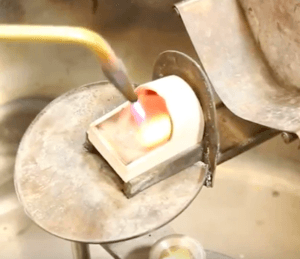

Amongst the array of dental services provided by clinicians, a significant portion of dental work involves advanced production outsourced to dental laboratories. These include crowns and bridges to replace broken down or missing teeth, full/partial dentures, appliances for treating sleep apnea or jaw growth abnormalities, or surgical templates for implant placement. Traditionally, clinicians will take an impression, or mold of teeth and surrounding structures and send this to a commercial lab. There, a technician will create stone models from this impression, and off of this impression he/she will create a mockup of the appliance sculpted from wax (this is commonly called a waxup). The technician then uses various laboratory technologies to convert the wax models into prostheses, appliances, and templates comprised of the final materials (porcelain, gold, acrylic, among others).

OLD METHOD

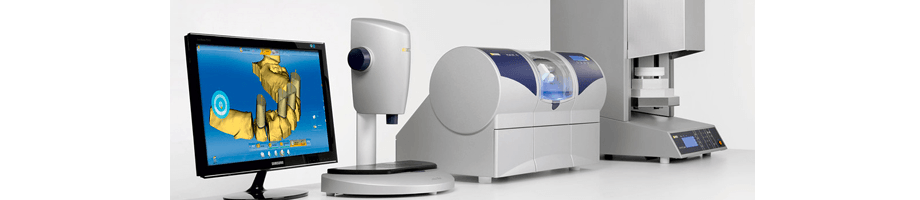

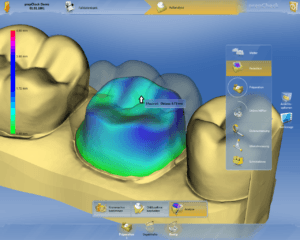

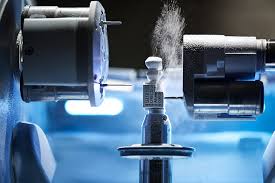

Over time, CAD/CAM technology has reduced lead-times and variable costs for commercial labs. Currently, most dental labs are equipped with 3D scanners similar to the Sirona CEREC system. Labs are able to scan their models and design products digitally, which drastically reduces the time for waxups. Subsequently, milling and 3D printing technologies allowed labs to fabricate products autonomously, with little human input.

At the outset, it has appeared that advanced scanning and fabrication capabilities have been a boon to commercial dental labs. However, lower costs and improved quality is threatening to turn CAD/CAM from ally to foe for laboratories. Sirona Dental’s recent campaign, titled “CAD/CAM for Everyone,” has aimed to deliver scanning and fabrication capability to every office, thereby reducing doctors’ reliance on commercial labs.

Digital impression systems and chairside milling technology are now affordable for many dental offices. Value to patients and providers is clear:

Patients

- Digital impressions are quicker and markedly more comfortable than conventional techniques.

- Since prostheses are fabricated in-house, patients no longer have to wait for final delivery wearing temporary crowns.

- Increased patient satisfaction and reduced health risk, since patients often break or dislodge temporary crowns/bridges.

Dentists

- Digital scanning provides analytics/measurements to improve accuracy and quality through feedback

- Units can be delivered in fewer appointments using less chair time

- Reducing costs (time cost for assistants, conventional impression materials, temporary crown materials, lab fees, remakes, shipping)

- Increasing revenue through higher patient turnover

- Premiums can also be placed on milled units since they use more advanced materials.

NEW METHOD:

While it may seem that commercial dental labs will become extinct, there are several opportunities for this industry to adapt to dental digitization. Commercial dental labs can adapt by:

- Leveraging the existing technology to reduce delivery times and provide on-demand services such as same-day delivery

- Creating systems to provide real-time consult to reduce errors and improve fabrication quality

- Achieving economies of scale ->move towards 100% utilization to reduce cost charged to dentists

- Vertically integrating to reduce cost and offer innovative materials technologies

Clearly, digital dentistry has offered vast improvements in the dental care delivery system and is here to stay. I hope that commercial dental labs adapt to these changes sooner rather than later to provide additional value to our patients.

LITERATURE

http://www.dentistryiq.com/articles/2013/06/sirona-grows-cad-cam-product-line.html

http://www.dentaleconomics.com/articles/print/volume-105/issue-7/macroeconomics/the-future-of-the-dental-lab-industry-the-lab-industry-ain-t-never-gonna-be-the-same.html

http://www.usatoday.com/story/news/nation/2014/04/06/dentist-digital-crowns/6267717/

http://www.dentistryiq.com/articles/2014/05/cad-cam-the-end-for-dental-labs-or-a-new-beginning.html

http://www.dentistrytoday.com/laboratory/1341–sp-489580286

http://www.dentaleconomics.com/articles/print/volume-98/issue-4/features/focus-on/the-latest-on-cad-cam.html

Where would the 3D machines be ideally positioned in the market? I can see individual clinics wanting to have more of the value chain under their control, but they would also be limited in their economies of scale. Also, does this change the reimbursement landscape associated with dental procedures that require molds? If all practices adopted 3-D molds that saved costs, would clinics then get reimbursed less from insurance companies since the average price of procedure is reduced? On a more fun note, maybe in the future, we will see a fad of customized dental moldings of various shapes and designs.

Good questions Philip. CAD/CAM is well positioned in the labs currently since they can use them closer to capacity than individual offices. However, it might not matter so much since the cost ($20 k for impression scanner, $80k for milling unit) has come down enough to that docs can pay this off in 1-3 years from saved lab fees. (It’s also possible for a doc act as a ‘lab’ for nearby clinic- thereby creating an additional profit center for the clinic). Reimbursements won’t change in the short-term. Milled units are cut from high-strength zirconia which is more expensive than conventional material used for crowns. Also docs probably pay a higher price for zirconia blocks compared to the labs, so they would probably compensate by keeping fees the same.

Hi Sina, thanks for this interesting post! For me, it is really exciting to learn some of the 3D printing applications in healthcare. I totally agree with you that the commercial dental labs should adapt to such change quickly and leverage this new technology to better serve the dentists. I learned that 3D printing also has strong potential in other medical devices like joint prosthesis. Similarly, this made me wondering whether 3D printing is an opportunity or a challenge for medical device companies, because hospitals themselves in the future can use 3D printing make many customized medical devices.

Nice points Ting! There’s still a lot of potential for the labs- they will be sticking around for a while. Master dental technicians undergo years of training and are invaluable in constructing more advanced restorations (esthetic dentures, implant-retained prosthetic work, etc). An interesting revenue source would be to provide on-demand consult for designing restorations digitally, since there is a steep learning curve for using the software that still prevents docs from adopting CEREC.

Sina, thanks for the great post on the future of dentistry. The molding examples you brought up bring me way back to when I had moldings done for my retainer. I remember losing my retainer at one point and having to have new moldings done – it was incredibly time-consuming and very expensive (for my parents). There is definitely improvement needed in this branch of dentistry and it’s exciting to see how close we are to experiencing that.

One question I have for you is regarding your suggestion of commercial dental labs becoming vertically integrated to take advantage of this new technology. It seems like the capex would be pretty large to introduce these printers into an operating model, and I would imagine this could lead to some consolidation in the commercial dental lab market. Assuming this worked and economies of scale were achieved, do you think any of these savings would be passed on to consumer? The Affordable Care Act has increased the number of Americans with dental coverage, but orthodontic work has historically been prohibitively expensive. Even so, over 40% of American adults still are not covered for dental care through insurance. It would be amazing if technology like this not only improved care for existing patients, but also increased the number of patients who could now afford care.

Source: American Dental Association – http://www.ada.org/~/media/ADA/Science%20and%20Research/HPI/Files/HPIBrief_1016_2.pdf

Great points David. You hit the nail on the head with consolidation. Days of the local small-time lab are numbered due to economies of scale that larger labs have. Lower shipping costs have also made it easier for docs to shop around for better deals. One of my attendings ships cases to a lab in Las Vegas that promises 4-5 day return (shorter than local labs, higher quality). The point about vertical integration meant that labs can experiment with materials to create a branded metal which they can sell to docs in block form (docs could use their machines to cut crowns out of this). Glidewell (http://glidewelldental.com) did this by designing their own Bruxzir line of anterior esthetic crowns.

As far as costs, I’m not sure how reimbursements will change, if it all. Sadly, it is hard to imagine dentists lowering their fees even if they’ve created efficiencies in their process. If this becomes widespread, perhaps insurance companies will reduce reimbursements in the future. In an interesting model is happening in orthodontics however. Smile Direct Club, is a new business that allows patients to take impressions on themselves, and the company mails Invisalign retainers they manufacture to fix malocclusion issues at $1500, which is $3500 less than the conventional cost of orthodontic treatment. It’s an interesting idea that actually takes the patient out of the operatory, which does introduce some ethical/legal questions regarding patient care.